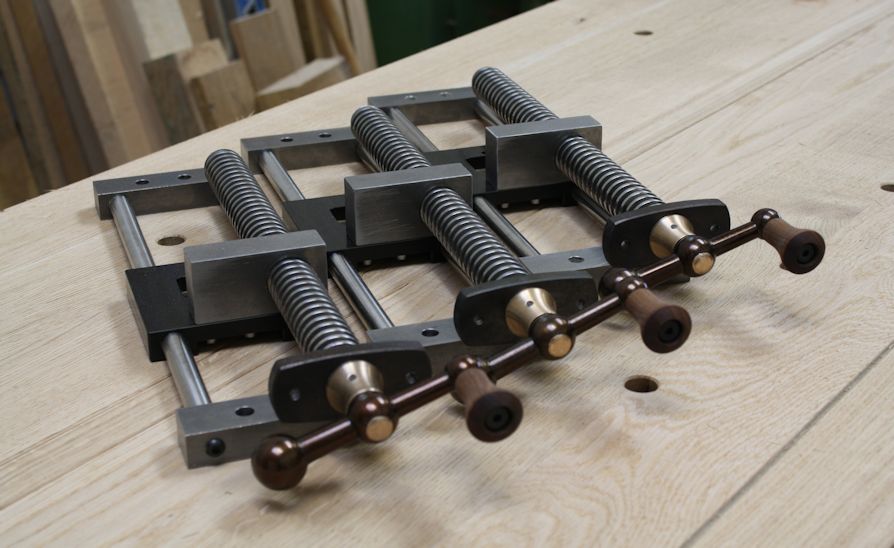

So apologies for the cheesy title and product promotion post but I thought it was about time that we had a further look at the MKII Maguire Wagon Vice. As explained earlier in the year we’ve given it a bit of an overhaul to tweak and make further improvements and enable us to keep up with demand by outsourcing some of the components to a local engineering firm.

We’ve been using and selling this new version since February time and have been absolutely thrilled with it. Amongst the improvements are a change to stainless steel for the two shafts to avoid rusting and a reduction in its thickness so the working parts are less visible once installed.

In use the biggest changes come from the efforts we’ve gone to achieve perfect tolerances between each of the moving parts. If something is too loose then things can shake about and disrupt the motion while a tight fit will obviously jar and cause friction. In this vice everything is just so – there’s a bush within the back plate of the handle, the carriage glides across the shafts and we’ve added a support on the moving carriage which sits under the thread to prevents it from dropping and affecting the feel. The result is a consistent action all the way along the travel and the only way I can think to describe it is it feels like winding air.

Whilst there’s very little weight in that handle it can be sent spinning with just one finger. We know this is true of every vice because we test fit each and every one here before they are boxed up and sent out. Something that we’ve been keen to ensure is that anyone installing the vice can achieve this beautifully smooth action without having to spend an unnecessary amount of time adjusting anything. So long as the templates are used correctly once this vice is secured in to the bench top it can be fine tuned for perfect spinning within a matter of seconds, that’s if it needs adjusting at all.

Since having the main components of the vice machined elsewhere we do still assemble, peen and attach the handles all ourselves so at busy times in the workshop this can result in a bit of a waiting time on vices orders. We’ve been particularly busy on vice sales of late with many going over seas to America and of course we are delighted about this; it’s encouraged us to aim at keeping completed wagon vices in stock and so we’re working very hard at present to make this the case.

Update: At the present time we’re not making any workbenches or vices for sale, however we have many resources on this website that will help guide you with your own workbench build.

Our English Workbench Video Series takes you step by step through a traditional bench build, starting out with a discussion on choosing the ideal dimensions, demonstrations of how to cut the joinery, right through to flattening your workbench top and building the face vice from scratch.

If you’d like us to guide you through your build with detailed videos and PDF plans, then you can find full details for this Workbench Series here.

![Simple Work Holding For Ploughing Grooves [Without a Tail Vice]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/07/workholding-without-tail-vice-copy.jpg)

![Gluing Up A Workbench Leg [VIDEO]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/06/gluing-up-a-workbench-leg-video.jpg)

It is nice to see that there are still people out there that put this much effort into their product,I have to say that it really is appreciated when it comes to using your vice,so many things that one buys now are just cobbled together (mostly in a foreign country) and sold at a quick profit,the fact that you control the manufacture from design to completion ,gives you total control,but it must be labour intensive!An excellent product.

Chris,

France.

Thanks Chris, we do certainly do things the long way here 🙂

It really comes down to that control element and we’re finding a nice balance in outsourcing some of the components locally whilst continuing to assemble and test everything ourselves.

Great work Richard, way to go buddy. 😉

Thanks Ken.

Congratulations,

The “old” one was already a looker, the new one is… simply stunning.

What would be the maximum width of a board that still fits vertically in the wagon vise? I understand this depends on a number of variables, like the size of the wooden dog block used, I just need a ballpark figure.

Alex,

The Netherlands

Thanks Alex, as you say the width varies a little dependant on the length of your dog block but tends to be about 200mm – 220mm. Hope this helps, we can also email through the installation instructions if required.

Richard,

I would like to see the installation instructions if it’s possible. I want to see how it would work on my existing bench.

Thank you,

Jeff

Hello, I want to know if your are selling the Maguire cast iron vise ? Either the leg vise and the tail vise. If so, what is the prices of it. Thank you very much.

Are these still available for purchase and if so where from please.