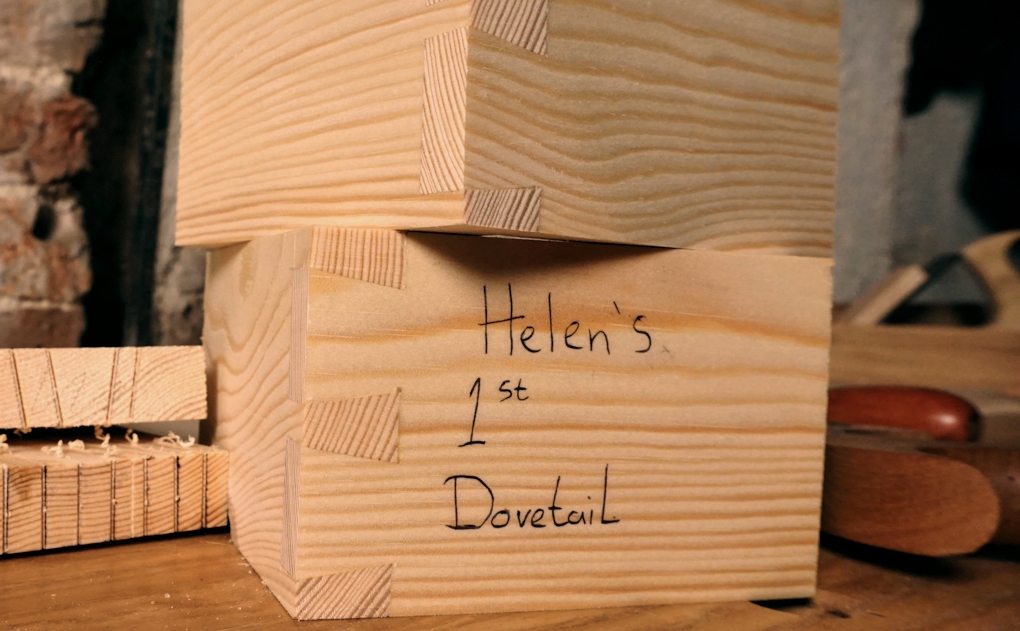

Yesterday I made my first hand cut dovetails. I’ve watched Richard cut dovetail joints over and over, and I’ve practiced cutting to my saw lines over even more.

Yesterday I made my first hand cut dovetails. I’ve watched Richard cut dovetail joints over and over, and I’ve practiced cutting to my saw lines over even more.

But I knew if I was left on my own, with just a few pointers, then I would still be about to make a mess of things.

Luckily for me, I wasn’t on my own. I had a teacher guiding my every step. Not doing any of the work, but instructing and identifying my beginner’s weaknesses.

Rather than cutting lots of joints, I repeated the individual techniques I was shown on separate boards, and focused more on the ones I struggled with. After a good few hours of tuition I was hitting home my first hand cut dovetails, straight off the saw.

The fit was snug, and once I’d planed over the surface (which panicked me seeing all that end grain), I could see the joint had seated home without any gaps.

This was curious.

I didn’t feel impressed, because I felt so adamantly that my first attempt at cutting dovetails wouldn’t look like this. Richard must have made a switch?

After a good break, I came back to attempt a second set of dovetails on my own. I took my time, but was finished in half an hour. Considerably quicker than the first.

The result was the same.

Not Just Beginner’s Luck

I’ve been cack-handed at most tasks I’ve approached in woodworking, so I know that I’m no natural.

My ability to cut a dovetail is entirely down to Richard’s guidance, and the fact that he knows the joint inside out.

The most valuable lesson seemed to be learning which areas needed to be made perfect, and which ones didn’t really matter.

There are many forms of education, and we all learn at different rates, but I struggle to see how I could have achieved better, or faster results from having a browse through a textbook. One day (far, far away) we shall complete our barns, and I will try twisting Richard’s arm so that he will offer tuition in the workshops.

Update: Want to make your own hand cut dovetails?

Enter our workshop… We now have a detailed video guide with Richard’s instruction for cutting both through and half blind dovetails.

These are stand alone joinery lessons included within our Spoon Rack Video Series.

![Which Saws Are Best For Ripping Thick Stuff? [Video]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/12/what-hand-saw-is-best-for-thick-rip-cuts.jpg)

![How do I Sharpen a Router Plane? [Q & A Video]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/11/how-to-sharpen-a-router-plane-video.jpg)

![Bench Top Edge Jointing [with Video]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/10/bench-top-edge-jointing-video.jpg)

“… which areas needed to be made perfect and which ones didn’t really matter.” Yep, spot on. There are always crucial bits and bits that aren’t so important in any job. The trick is to know what and where they are.

Excellent first crack at these, by the way. Secret mitres next please, by the following weekend.

Thanks Rob, consider it done 😉

“…which areas… didn’t really matter.” Almost sounds wrong!

Well done Helen, nice job 😉

Those joints look great, Helen. Keep up the good work 🙂

Beautifully done. 🙂

Congratulations Helen. None of mine ever look that good 🙂

I sometimes go a long while without cutting dovetails. Frequency helps proficiency. I worked for a time with a fellow who grabbed a piece of scrap every day and cut one dovetail. When the time came to do it where it counted, he was fast and accurate. I should follow his example.

It’s surprised me with hand tool woodworking how much of it’s repetition, if you’re not planning to a line you’re cutting to a line, so most jobs compliment each other. Cutting a dovetail a day sounds like a good idea… I’m not sure I’d stick to it though!

Spot on!

In the immortal words of Lone Watie (Chief Dan George), “endeavor to persevere.” The Outlaw Josey Wales, 1976 (https://en.wikipedia.org/wiki/The_Outlaw_Josey_Wales).

Spot on job Helen, you are better than you give yourself credit. Perseverance pays dividends, or in your case, nice dovetails.

Cheers,

Mike O’Brien

Valley Head, AL, USA

“Crackin’ joints” has such completely different meanings in the US vs. the UK, Helen. Hopefully you know in which way I now use it.

Richard has a great pupil there. Wonderful work; keep it up!

Everything over here’s just a “crackin’ good job!”, so I’ll take that as a compliment. Thank you 🙂

Job well done, Helen.

Only those who have patience to do simple things perfectly

ever acquire the skill to do difficult things easily.

James J. Corbett

We were all cack-handed when we started. We all make countless mistakes and learn from them.

Every skill we learn is divided into small bits, and the small bits, when put together, make difficult tasks look and feel easier every time we do them.

You have a good mentor there.

Wonderful work Helen! Just finished the Anarchist’s tool chest and mine don’t look any better. Maybe Richard would let you come to the states and teach the rest of us.

Thanks Dave. I’ll get my bags packed… I’m sure I can blag my way through 😉

Very good! Looks like you’ve been at it for years. Just goes to show a little saw practice goes a long way.

My dovetails look pretty now. I can promise you that my first didn’t look anywhere near as nice as Helen’s. Good job.

Helen,

Impressive, the teacher may be a master craftsman — writes like he is finishing his PHD. The Student gets high marks for her first joint by hand. 3 cheers.

You both do great work in front and behind the camera, writing and creating – no wonder Christopher Schwarz has invited you work to write a book. I believe that it is the two of you that make the whole site a joy. Keep up the great work.

thank you both — I wish I could make such joints by hand.

cheers

” – no wonder Christopher Schwarz has invited you work to write a book…”

Really! I’d buy it. I already set up my metal planes like Richard sets up his double iron woodies. Works fantastic. I wonder what other goodies he’s not let loose upon the world yet…

Helen, that joint looks fantastic! Saw the rest off, finish it, mount it on a plaque and stick that thing up on the wall. Looks right proper. Good job!

Well done Helen, you made a lovely job of those dovetails, really impressive for a first time. I’m enjoying your journey on the woodwork path.

Great job by the teacher. Most impressive job by the student. I can only hope someday my joints look like those.

Excellent job.

As a student/new learner, you might do well to make a video showing the technique as well as what does and doesn’t need to be perfect while it is still fresh for you (and Richard as guide).

Color me most impressed. I tend to only remember the “unimportant” nuances/areas at the “halfway through the job” point.

I need to do them more often.

Hats off to both- the fine student, and the good teacher.

Another milestone! Well done.

Now the bug has bitten there will be hundreds more to come,well done

A lot better then mine! good job

Helen,

your dovetails are looking wonderful.

My first weren’t that nice. But one thing I’m still wondering about is that my first dovetails were better than the following ones.

My assumption is that the first joint gets a lot of attention and then in the following projects the attention gets lost because oneself thinks you are are familiar with the technique now,

Cheers,

Stefan

Very nice work Helen. I know you have a decent tutor ;)… but there is real native talent in there.