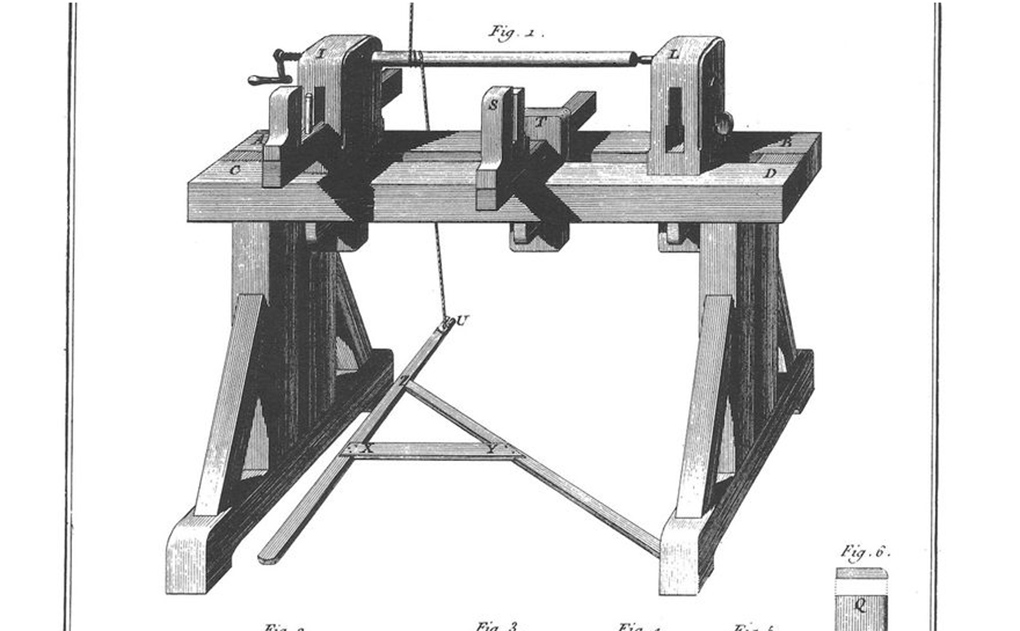

Before I delve deeper in to the subject of workbench design I’d first like to draw attention to one of the unsung heroes of my workshop. My Saw Donkey’s (as I like to call them) are my more humble yet resilient version of a saw horse.

Alongside a well designed workbench I don’t think that any workshop can be quite complete without some form of saw horse and they will be indispensable even if you’re only using them whilst sawing rough boards to length.

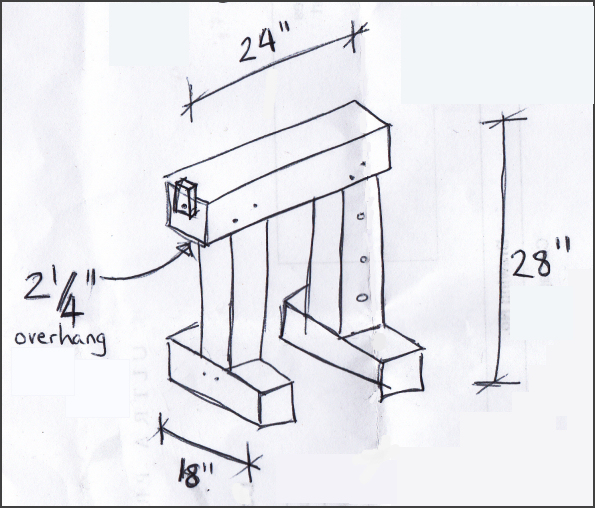

The more conventional, triangular design has always been popular but I like to beef things up a bit (I guess it comes with the job) so when I built mine I opted for the timber framer’s version. This is a simple design built tough through large draw bored joinery and I find a lot of benefits over the other variants especially as they’re strong enough to hold six workbench tops all stacked up without buckling at the knees! And when I don’t need to hold quite that much I find the design works great as a mini, mobile workbench as the top is broad and so well supported underneath that you can clout away on top of it no problem. Like the ’French’ workbench these ‘donkeys’ have their legs flush with the top so it’s easy to add holes down the leg for dogs or a holdfast and maybe even screw a little stop to one side.

If I was back in the days using these exclusively for furniture making then I would definitely build them a lot lower – around knee cap height should work well.

Mine are 28” tall because I use them for a multitude of tasks whilst bench building and a lot of the time this is as a pair of trestles to simply hold a mass of timber lengths whilst I run them through the planer. Also, when I’m building a particularly tall bench, they come in to the support the top whilst I do the initial flattening and so 28” works well.

As a pair these can become both saw horses and a saw bench in one and they will stack together fairly compact as well. I’ve build mine from 4” square timbers but 3” ought to be adequate.

Choosing & Using Hand Planes – A Video Rant

Thanks Richard, I like them buddy, another One for the must make list.

Very Best

Ken

Nice.

Going to make myself a pair of these out of 4×4 doug fir.

You can not use the name “Saw Donkey”. It is registered to my company.

Please remove this name from you site or legal action will be taken.

Thank you.

Really? You are joking, right?

Is “Saw Ass” taken? 😳👍😜

What are the dimensions for the mortises and tenons.

Thank you

Rich

They’ll hold up a lot better if you add a stretcher near the bottom

Why not put two holes in for holdfasts?

I’m making a pair out of oak at the moment and pondering ways to keep stuff steady. They will be way too heavy, of course, and used for working on timber for log houses….