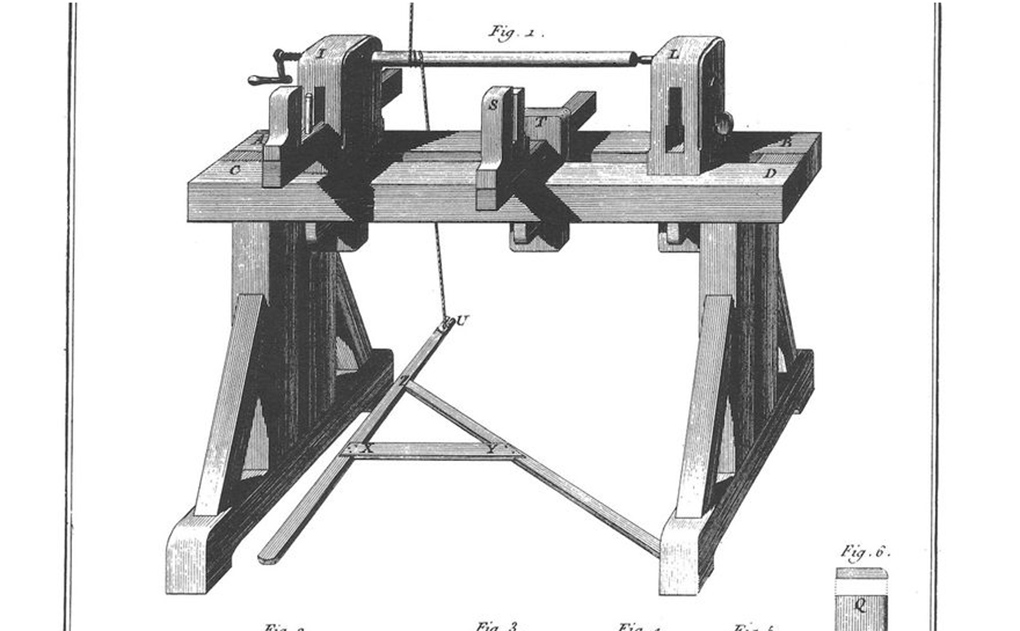

This image is from Gary at the Toolmera Press website

I have a few jobs coming up that require turnings, turnings that are quite a bit bigger than my little compact bungee bench lathe. Some of the turnings are also out of the heavier stuff, so my little compact bungee wouldn’t only need more length, but it would need to be of a much heavier build as well.

At least that’s what I’m telling myself.

It’s an excuse you see, fabricated so I can justify the build of Roubo’s lathe (do you ever do that?).

Just like his bench, Roubo’s lathe is of a rather heavy build. This is critical, as most of what I’ll turn is of the dry stuff, which requires a lot more force than the wet green stuff, that we mostly associate pole lathes with.

A lot of us will have seen Roubo’s scratty drawing of the lathe (which is shown above) and with all of his writing being in old French, I thought this is all I’d have to go off. But… oh no… I got very lucky and stumbled across this, The Christian Tool Cabinet were Bob Jones’ interest in the lathe had led to Don McConnell of Old Street Tool, Inc providing a transcription of the text, which Bob has made effort to translate. That’s about 5000 words, all on that lathe… I’ve read it about ten times, made notes, but still haven’t fully digested it.

If you have time, I urge you to pop over there and have a read, then we can get back to talking about this lathe. Having more minds on this is certainly going to help… Also leave a little thanks, a huge thanks to Bob, Don and Gary, three more names on my pot of tea/pint list.

More to follow.

Richard,

When I asked you a while ago: “Why don’t you build yourself a proper bed?”, this is not what I had in mind. 🙂

I will read the text later and see what I find.

Perhaps there’s someone near you who has a large lathe? One does not have to own everything. I mean, this is a hefty contraption. But I understand it is a good excuse…

Have you also considered a treadle lathe? I’ve been vacillating between spring pole and treadle and am thinking the treadle will be more difficult to make, but easier to use. And since I’m a novice turner, but comfortable with the build process, I may follow the path of least resistance.

I am extremely interested in this conversation, whichever way it may turn though.

Umm… Google Translate yields texts that allow you to catch the gist of what is said, if the text is not too complicated and uses a modern vocabulary. Putting in Roubo… Well, the result uses English words and I’ll grant it seems to cover the same subject. Trying to piece together the details of this lathe’s construction? I’d say you’re better off trying to find a woodworker who speaks French.

This is my favorite part.

“Masters where Carpenters are not turners, and as this book is for all countries equally, it would be make it incomplete if I did do not cover at least the basics of the lathe (Tour a pointe), which strictly speaking, the Carpenters can do without, at least for ordinary works.”

I think there are simpler designs than Roubo’s. Most of the time I see his double legs replaced by a larger single leg (extended to a fixed head on one side). This can simplify the joinery. He was mostly modern, by the nineteenth century the Tour a pointe is dated: no bearings or treadle.

Try contacting Don Williams at:

http://donsbarn.com/contact/

He might have the section already translated for the next Roubo volume coming soon via Lost Art Press and could definitely provide some valuable insight.

Good luck.

Hi,

Thank you Richard for this inspiring post. If I may add for all your readers:

While reading that 5000 word translatio, I felt I desperately needed drawings to generate a better understanding. As Richard mentioned the reference to the Toolmera blog as the source for the picture in his post, I headed over there and was happy to see 2 complete drawings, have a look at: http://toolemerablog.typepad.com/toolemera/2012/01/roubo-spring-pole-lathe-images.html

(There is also a download link on that webpage for a high-resolution PDF of the drawings)

In addition, I also enjoyed the interview with early Roubo lathe pioneer Warren Mickley on the the christian tool cabinet blog. (https://thechristiantoolcabinet.wordpress.com/2014/01/12/roubo-lathe-in-use-today/)

This is great information, Igor. Thank you.

Richard, I can see this is going to be an interesting project and not one to be “knock-up in five minutes”.

If you do take it on, I for one would like to hear how you get along with it. And it would be even better if you were to ask Helen to film the build, so we could ALL see how you get along with it.

Anyway, if you do take on.

Best of Luck Lad, and I hope it all goes well.

I visited a small historical museum in Aurora, Oregon, USA, (south of Portland) about 50 years ago. In the collection was a massive, wooden, flywheel lathe. It was so large that the operator stood on a raised plank walkway to operate it. The treadle ran the full length of the machine which was somewhere around 10′ between centers. The description said it was used to turn fancy porch posts for the community, a quasi-socialist utopian group, IIRC. It was an impressive machine, obviously made by the woodworkers, with contributions by a skilled blacksmith. It dated from sometime in the second half of the 19th century.

Does anyone else think that lathe looks like it has been designed for someone who is left handed and footed? It’s got the screw advanced centre on the left hand side and the treadle looks like it’s easier to to push with your left foot. In my experience it’s nicer to use a treadle that you can easily use with either foot so that you can give you dominant leg a rest. Mike Abbots design is good like that. His also includes the ability to steer the cord up and down your work so you can change the position of the cord without moving the treadle.

David, if I may, Have you seen any plans for a lathe powered by a bicycle wheel, utilizing a gear, chain, freewheel and pedal for power. Enjoy your emails immensely. Tom Lokken