Whenever I’ve taken my workbenches out to a show I’ve always enjoyed lovely feedback and appreciation. One line that I can guarantee will come up at least a dozen times though is “it’s too beautiful to use!”. You’ll think I’m mean but it’s always that line that leaves me feels somewhat deflated – it’s put across as a compliment but I take it as a kick in the knackers! What’s the point in a workbench that can’t be used … it would be like having wings but not being able to fly!

Now I’m not suggesting that I don’t want my work to be appreciated for how it looks; I do feel that we can get a lot of encouragement from our tools if they’re nice to handle and admire as well as to use. This can add pleasure to our work and keep us reaching for a high level of finish in the items that we build with them.

Update: At the present time we’re not making any workbenches for sale, however we have many resources on this website that will help guide you with your own workbench build.

Our English Workbench Video Series takes you step by step through a traditional bench build, starting out with a discussion on choosing the ideal dimensions, demonstrations of how to cut the joinery, right through to flattening your workbench top and building the face vice from scratch.

If you’d like us to guide you through your build with detailed videos and PDF plans, then you can find full details for this Workbench Series here.

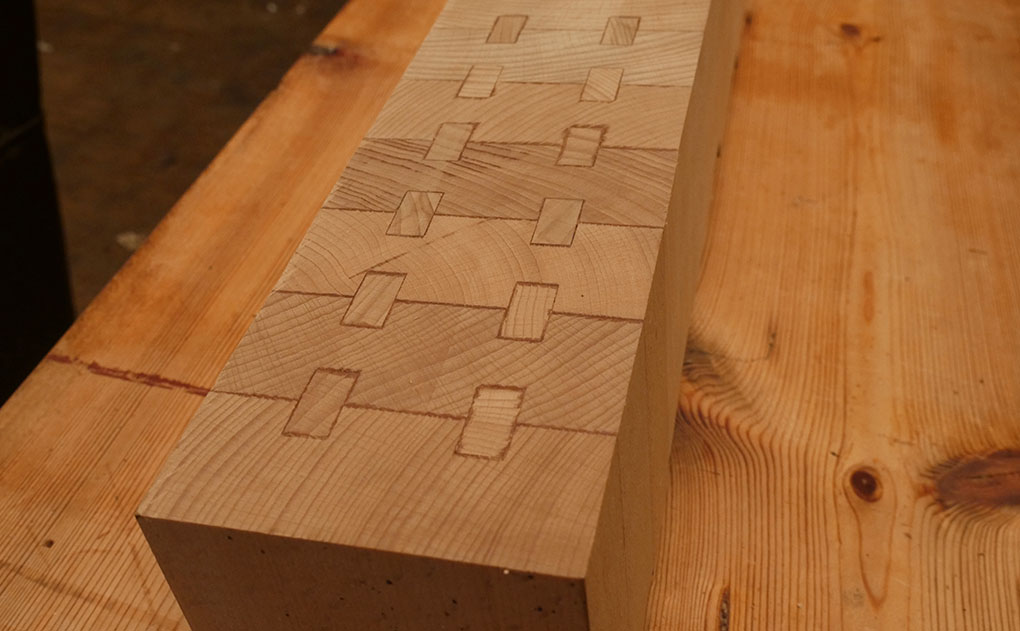

There are a good number of wonderful hand tools being made where priority is purposefully put on an ability to be appreciated, displayed and admired over being put through a hard days graft but I like to think of my workbenches the opposite way around. They are firstly designed for function with every area thought through to ensure they provide the user with maximum versatility and strength. The timbers used are large in section and the traditional joinery is draw bored – both are to give strength, stability and long life to the bench but also result in sound proportions and lovely peg details that are pleasing to the eye. In other words the beauty comes from designing for function and being fit for purpose. The final thought goes to the subtle details such as the curves on the hub of the wooden screws which are a finishing touch on something that’s already there.

There’s a lot of strong opinion on what’s right and wrong when it comes to workbench design and I think this illustrates their importance within our workshops. It also illustrates just how personal a good workbench is and I feel this is the vital point to take away. Whilst I’m building workbenches for sale I’m also aware that many woodworkers are browsing through the web to get inspiration for their own workbench builds. Workbench design shouldn’t be about seeing something you like the look of and copying it detail for detail as one person’s needs differ to the next. Whether you are building or buying a workbench you should understand what your requirements are before making any decisions. A snazzy vice might look the part but if your bench rocks from side to side just for looking at it then you would have been better off getting the basics right first. I design workbenches that are the best that I can create for that price range and whether that is £800 or £3000 I’ll always make sure that the priority is on function.

I’m going to try and suggest a few pointers from time to time and these will be filed in a new category on the blog called ’Workbench Design’. It’s not rocket science but it might help out if you’re feeling a bit confused.

![Simple Work Holding For Ploughing Grooves [Without a Tail Vice]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/07/workholding-without-tail-vice-copy.jpg)

![Gluing Up A Workbench Leg [VIDEO]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/06/gluing-up-a-workbench-leg-video.jpg)

Very nice workbench. As for “too pretty to use”; the marks of use are what give nouns character. ☺

Thanks Dave, that’s very well put and I have to agree. A few dents and scuffs only add to the appeal in my book!

love the clean lines of the bench, would love to get my hands and place some timber and tools on it for sure, How about some close ups of that bench, construction for us all to see 🙂

Thanks David, there are a few more photos of this bench in a previous post that shows a bit about how its put together – https://www.theenglishwoodworker.com/?p=440

Cheers,

Richard.

well I have to say there is some truth to the “too pretty to use” sentiment… in the shop where I learned we had some more or less beat up workbenches made of beech with holes and bits of paint and glue and surfaces that were from time to time sanded – not planed down – so I definitely think that I would work differently if I had one of your benches – taking care not to drill or chisel or saw into the bench, always using something to protect it when working with paint and glue etc. maybe “too pretty to treat it the way I have admittedly treated other benches…”

That’s a good point, I think if you know something’s a bit more disposable then you are inclined to treat it with less respect and care than you could. With my particularly nice hand tools, say my Clifton no. 7 or any of my Philly Planes I want to be sure I look after them despite the abuse they get being used daily. Every few months I have to strip them down and give them a good clean & wax to keep them in good condition, then away I go again. They still bear battle scars as any hard worked tool but they remain beautiful and for me the true beauty is when they’re being used.

Thanks, Richard.

Form follows function is quite an apt description for your benches mate.

Thanks Patrick, I think with a tool it can’t be any other 🙂

I agree, sometimes something can be so great at fulfilling its function it can increase its beauty.

I feel the same way about some woods, how they feel to work and how strong and resilient they are makes them look even better when finished. In that I think your benches and English Oak make a perfect partnership.

What species of wood is that?

Hi Dean, it’s some lovely English oak as I thought that would suit an English bench! It’s been finished with many coats of tung oil to give it that warm colouring and it also makes it hard as nails.

Cheers.

It certainly looks fantastic. I’ve read a lot that iron and steel will react with oak and leave black stains; is this something you have experienced?

Hi Dave, This staining will definately happen if the oak’s slightly wet but with well dried oak like this I have never found it to be an issue, especially with most of the hardware being wooden. I use several coats of oil to finish the oak and this soaks a good way in which really prevents any concerns with iron touching the raw oak. If I’m using oak that’s thicker than 4″ then I source timber that has been drying for a good 50+ years, this may sound extreme but it’s surprising how long timber takes to dry at thicker sections. I’ve looked at using some 6″ x 6″ beams in the past for legs and at the time they were 10-12 years air dried in a barn – when I cut them in half they were very wet in the centre so I had to leave them for something in the future. If I put a steel vice screw through one of these ‘legs’ then the acid in the wood would react badly and cause staining to the wood and rot the screw.

Well Richard…I have to sympathize with the people who make those comments about your workbenches but I will also vouch for your point of view. Your workbenches are very beautiful, as an owner of the Nautilus I can say that it hurts a little when I make any kind of damage to it or get a bit of glue on it. I always make sure it stays clean after working on it because it is a work of art, even if it is meant to be a tool that gets used and abused. Speaking of working on it though, it is state of the art, the vices work flawlessly, clamp with perfectly, the bench doesn’t move no matter how much force you put on it, I couldn’t ask for anything more! Keep up the great work.

Cheers from the US!

Hi Scott, thanks for such kind comments, it’s made my day! I think the first scuff is always the hardest and I’ve heard it only gets easier from there! I’m pleased you’re putting it through it’s paces.

Thanks again, Richard

I confess that when my Modern Workhorse bench arrived a couple of years ago, I did spend a few days (weeks!) looking at it, but it’s had plenty of use now and still looks as good as when I bought it from you; a few dings and knocks sure, but that adds to the character!

Thanks Ellis, it’s lovely to hear from you snd I still haven’t forgotten your offer for a cup of tea… one day I will pop by, I never forget a man who offers me tea!

Thank you Richard. You couldn’t have picked a better wood. It looks fantastic!

That is one fine looking bench. You could only hope that anything made on that bench would come out looking as good. Really. That bench is awesome.

Hi Scott, thanks for your kind comment, your support goes a long way.

I have a friend who makes tables and benches and at the final move out the door he hits it with a hammer somewhere and says, “Now you won’t be afraid to use this.” Same way we do witha new vehicle!