I was having a good old rummage through the timber store the other day and found an old off cut from a workbench top. It’s from one that I made when I was building them for a living.

I used to keep these off cuts and put them to the test. Sun exposure, damp, all that to see how the laminates held up.

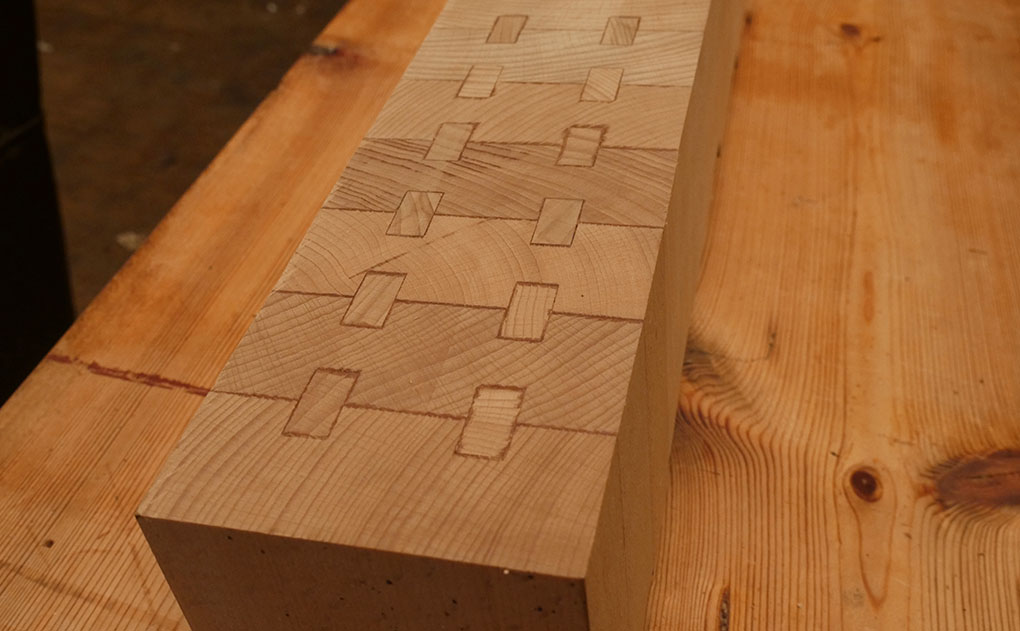

When I looked at this one, I was shocked at the amount of work that went in to one of these.

I was obsessed about bench tops, and was constantly testing and bettering. All at the expense of myself.

The workbench this top came from sold for £3800.

That’s a lot of money for a workbench.

But… I was getting prices the other day for full staff wooden worktops. Properly made jobs for a posh kitchen.

For a top on its own, 2″ thick at 3 meters long with the vat included it wasn’t far off the price of that entire workbench.

The bench of course also had almost a grands worth of custom vice hardware on it.

And the tops couldn’t be compared. These kitchen ones are only edge jointed – nothing else added, and my top was 5 inch think!

Pricing is funny.

As a craftsman pricing up your own time is maybe the hardest part. And when most of what you’re making you couldn’t afford yourself, the weirdness of pricing becomes more apparent.

It’s rarely based on the work required, and much more what someone is willing to pay.

The workbench tops became a bit of an obsession. After all, I was putting my name to these things.

I’d always plane many more laminates than needed, and then test the moisture of each staff.

There had to be less than two percent difference between each of them, or they’d not be used. They were then individually hand planed to give an ever so slight concave face, all to ensure a strong joint. Then they’d be grooved and tongues made to be added.

It was a long process.

And get ready for the best part….. the early ones were planed right from the start entirely by hand!

That thought alone triggers panic attacks.

I’m very proud of my workbenches and I did make a living at it. It taught me how to work long hours and become efficient. Character building.

It Also Taught Me To Find A Simpler Way

With such an obsession to create a stable workbench top, I’ve explored all ideas on this topic and learnt that the most simple approach really can be as good.

Before you get sucked in to going over the top for your own workbench build, have a read of this post showing how well my planked top has stood up to the test of time, and why this works.

As a final note, our latest video build – The Retro Sideboard is now approaching completion. You can find the details here if you’d like to catch the introductory discount.

![Simple Work Holding For Ploughing Grooves [Without a Tail Vice]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/07/workholding-without-tail-vice-copy.jpg)

![Gluing Up A Workbench Leg [VIDEO]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/06/gluing-up-a-workbench-leg-video.jpg)

Richard,

Your laminates were (are) impressive. Hard to make a living doing that by hand. What glue did you prefer to use? Any thoughts about making vise screws again.

James 🙂

When are you starting your real world workshop classes Richard?

For us it is funny, for yourself… maybe by now as well?

Thanks for sharing your insights!

My cutoff’s from my workbench made a nice 3″ thick end grain cutting board.

I doubt that bench is moving anywhere, nice jointery

Mark

Thank you for this post. I had already been convinced of your excellent craftsmanship, but this blew me away. If the missus became angry and torched his bench it would have burned for a week! Anyway, I consider myself quite fortunate to have come across your site and am every more happy being a subscriber. The build videos I have purchased are money well spent!

Sh-t! the bed Richard!

Excuse my French , but bloody hell there’s some blood sweat and tears been put into that bench I hope the customer appreciated it , a can’t imagine you made much profit on that one.

A tell you what I’m glad that bench wasn’t the work bench build or think I would still be

using me black and decker work bench and not me English work bench haha!

As for pricing work ,I always find that’s the hardest part to get right , some you win some you lose

Ste

That workbench is so solid and so flat your customer has probably covered it with felt and plays snooker on it.

Did it not strike you as odd that he kept insisting it had to be 6 x 12 ft and to leave spaces at the corners and halfway along?

I often think of you and your craftmanship and the diligence you show towards your work when I see some YouTube “Maker” bang two hardwoods together with a nailgun and “…call it done”. Yours will still be here in two hundred years. Theirs will have long since added to the global CO2.

As a proud owner of one of you workbenches I can only say thank you. Your bench holds pride of place in my workshop and it works so well.

I echo that Paul as I am also a very proud owner of one of Richard’s workbenches. It takes pride of place at one end of my workshop with space around all sides so it can be admired from all angles.