I knocked myself up a couple of saw horses yesterday from some old bits of pine I found laying around in one of the barns. I’ve already been forgetting to take tools on my travels between the workshops so I didn’t want to start carting saw horses around with me as well. With these built I’m now all set to start work on my new bench and I thought it would be a good time to explain why I’ve opted to go English.

If you’ve read my previous posts ( 1 & 2 ) on this bench then you’ll have noted that this is going to be my prepping workbench which I will be both building and using without the aid of machines. I’ve never felt that there’s one particular style of workbench that will be best for all situations but there are many reasons why I feel the traditional English approach is an ideal match for me here. I noted earlier that the majority of workbenches which I’ve built for customer’s over the years have been based on the French design and I’d say that the reason for this is down to the versatility of that design.

If you’ve read my previous posts ( 1 & 2 ) on this bench then you’ll have noted that this is going to be my prepping workbench which I will be both building and using without the aid of machines. I’ve never felt that there’s one particular style of workbench that will be best for all situations but there are many reasons why I feel the traditional English approach is an ideal match for me here. I noted earlier that the majority of workbenches which I’ve built for customer’s over the years have been based on the French design and I’d say that the reason for this is down to the versatility of that design.

In their raw form both the English and the French style of workbench support the same type of working methods but the difference is in the ability of the French design to more easily adapt to suit a more modern way of working. We’ve offered and sold English type workbenches in the past and whilst I can’t be sure specifically why they have never sold as well I was nearly always asked to add a tail vice so I can presume that the lack of this is a turn off.

The simple and robust design of the French bench gives it a strong presence and I belive this has been further enhanced by it’s popularity in recent years; many woodworker’s have built beautiful examples in fine hardwoods and with expensive hardware which must really add to the design’s appeal.

The English bench whilst also simple is less easy to alter and is more likely to be seen built in construction grade timber than anything fancy. Bolting on modern additions such as a posh tail vice is also less likely since the deep front apron makes raising the bench dogs unpractical.

In my opinion the English workbench is best left in it’s original form to be used for a more raw way of woodworking where work is held with stops, battens and the worker’s arse. The English bench is a hard sell for modern woodworking when compared with the French and as a result we don’t often see it being used to promote new vices or bench add on in the same way which means it gets less publicity than what it perhaps deserves.

The French bench is beautiful to work off and so adaptable to our needs but I’m building this one English because there is nothing I wish to adapt. It won’t be the most attractive bench I’ve built but it will be ideal for constructing by hand.

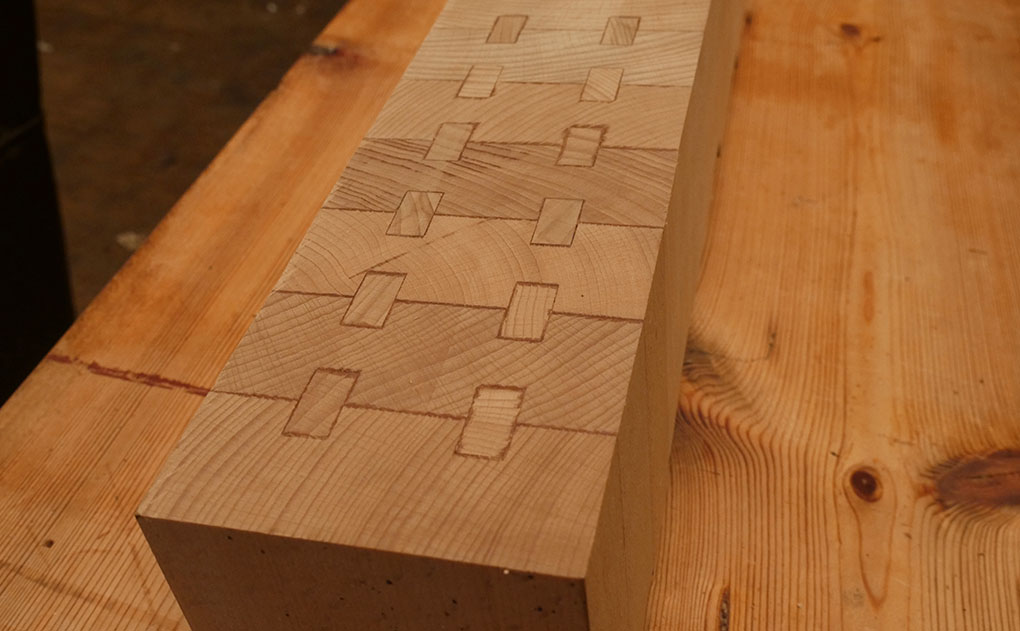

The pinnacle point for which I’ve chose this design is because even hundreds of years after it’s first use I can go in to any builder’s merchants and pick up materials which ideally suit it’s construction. There’s no need to laminate to build up larger sections and this means it can be built quickly and simply all by hand.

We take you step by step through a traditional bench build, starting out with a discussion on choosing the ideal dimensions, demonstrations of how to cut the joinery, right through to flattening your workbench top and building the face vice from scratch.If you’d like us to guide you through your build with detailed videos and PDF plans, then you can find full details for this Workbench Series here.

![Simple Work Holding For Ploughing Grooves [Without a Tail Vice]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/07/workholding-without-tail-vice-copy.jpg)

![Gluing Up A Workbench Leg [VIDEO]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/06/gluing-up-a-workbench-leg-video.jpg)

Look forward to seeing the end result

Great to see work in progress, every day a step closer buddy. Thanks for this one Richard. 😉

I say lets promote the English bench a bit more its about time it had some recognition

Richard, a very well written and thought-out explanation, especially when combined with your video on Holdfasts and Battens.

https://www.theenglishwoodworker.com/?p=1434.

You have given me a greater “real-world” understanding of these two styles of benches than I ever had before. Thank you for that.

The shop looks awesome. I can’t wait to see more!

The English style bench is great, very easy to build and appropriate for most types of woodworking. Nice to see a Sandvik hardpoint in the shot, last time it was the splitproofs that gave me the nostalgia hit.

Thanks Richard – but you make no mention of the saw horses!! will these be explained/shown in a later blog?

Cheers

Frank

You have convinced me on hold downs. I have never used them before seeing your video, now I can’t think of NOT using them for everything, I use the Battens as well, so I have to tell you I am really looking forward to seeing how you construct your English work bench. The one I currently use is pretty useless as it is only 24″ wide and screwed down to another 24″ wide cheap Box Store(Chinese)one at 90 degrees wrapped around my table saw. I hope to redo my whole shop after seeing what you do here. I am particularly curious as to how the large front apron will work out for building and using hold downs. I’m thinking that an end vise just might be something that wouldn’t get a lot of use in respect to the front hold downs?

Slainte!

Micheal

First off thanks for the blog and videos. They are both informative and entertaining. It enriches all of us to see you making a place for yourself and sharing it with others.

I am getting ready to make a new bench based on the English style (with some modifications). I am leaning towards a laminate top out of concern that one and a half inch thick construction lumber will not be rigid enough and may not provide ample holding power for the holdfasts .

Any thoughts you might have will be appreciated.

Thanks Don

Richard, I like the simplicity of the English bench. It’s easier to build, and very sturdy. I must say, though, after using a German bench recently, I do love a good tail vise! Can’t wait to see your build.

‘the worker’s arse’…Might make a catchy nickname for this type of bench.

I’m looking forward to this Richard, especially since I am building an English style bench at the moment.

I’ve been debating on the use of nails vs. screws.

I look forward to you elaborating more on the nails shown in that picture. Soon… I hope.

Can you direct me to a website showing a photo of an English workbench? Doing an internet search throws up many styles, apron fronted, splayed legs, etc.

Richard, do you know the date origins of this apron style of workbench? My work necessitates using the 17th century as a reference, so naturally Moxon is my main data point. Moxon’s bench is quite different than this apron style, and I was curious if you know when the English transitioned over to this style.