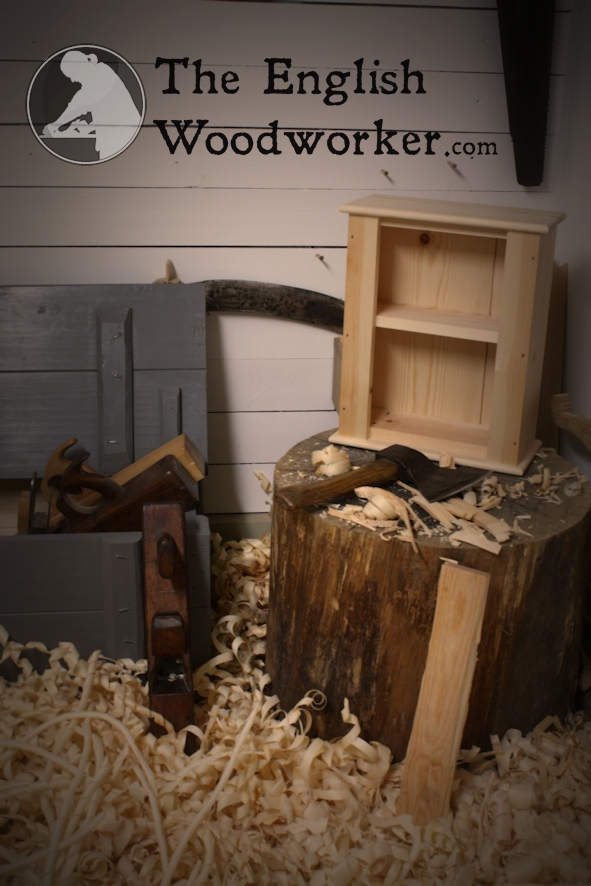

Setting up my hand tool workshop for the filming has been quite a revelation for me as it’s allowed me to spend the odd weekend in there feeling a million miles from the rest of the world. Since I’ve always been woodworking for my living this is a feeling that I’ve only rarely been able to get a glimpse of. Despite being very much enjoyable if it’s work then it’s always going to feel like work to one extent or another! It’s funny how separating the hand tool space with a wall has made such a bloody difference; I’ve always been able to potter with bits and pieces but now the change of scene feels like it’s given me something new. When i slam the door shut I find myself in the mist of a hobby and I’m always itching to get in there and smell the shavings!

There are two main differences this hobby allows me; I can pick and choose exactly what I feel like making and perhaps the strangest feeling is it doesn’t matter if I don’t work to the best that I can.

Before I started building workbenches it was all furniture and whilst I spent the majority of my time delving and studying in to the history through a hunger to learn I’d find it very difficult to find commissions that would really warrant the time I spent building them. The furniture was built entirely by hand because that was where my heart was but the commissions didn’t suit it – a classic being an authentic 16th century TV unit!

Since firing up with the filming I’ve really found that hunger for it again and this time I can do it all my way without having to worry about if I’m being paid enough to eat. The cupboard is getting wrapped up shortly and so I’m looking forward to choosing what will be next… any ideas?

The amateur has it so right. Thank you all for reigniting that fire!

Hi Richard, nice post once again. What to make next, just some ideas of the top of my head.

Small table

Stool

coat rack

dovetailed box

dvd / cd storage

small book case

Cheers 😉

Thanks Ken, no shortage of ideas there then! 😉

Hi Richard & Helen,

Hope all is well and you are organised for the European WW Show.

As ever, this is a great post, and I thought I would add my two pence…

As Ken has suggested, a Stool would be a great idea!

I’d like to be able to make one for the workshop that is high enough to sit on at the workbench when

working on joinery, but as I don’t have a lathe then it needs to be made without one.

Come to think of it, maybe you should show us how to make a treadle or spring pole lathe…

Either way I’m sure what ever you choose will be great.

Cheers, Stephen.

P.S. I managed to get the carcase for my ATC tool chest dovetailed and cleaned up, not bad for 18 months work!

Hi Stephen, a stool does sound like an interesting one, I’ve never actually sat and worked at a bench before. Building without a lathe would certainly add to it as well.

As for the show, all I’ll say is we’re starting to panic!

Pleased to hear you’re cracking on with your chest… At this rate by the time it’s finished it should just about class as an antique! Would love to see photos.

Hi Richard,

I already finished the cupboard and I’m waiting to compare what I did to what you did. This little cupboard taught me a lot.

I would like see anything again that the cupboard had – ripping to width – cross cutting and squaring. I especially like thinning boards down and would like to see more of that.

I would like to see some videos on ripping boards to width and thickness planing by hand as it is something that would allow me to rely on carting all my project stock to school and cutting it in the machines there.

As I’m still very much a beginner I think it would teach me a lot about the craft and Richard your no-nonsense straight explanations are easy to follow and understand. Maybe you could make a project out of a single board such as a grooved box etc.

Hi James, that’s a nice suggestion. Prep work could probably make a nice little series since there are so many different situations which can be covered and I like the idea of turning the thicknessed board in to a small project such as a box.

Cheers

hi Richard. like James i am very much a beginner a solely rely on hand tool truing an thickness stock would be very educational.regards david

Thanks Ralph, I read your posts on your blog and I did chuckle that you weren’t hanging around for me! All I’ll say is your latch was spot on! I really enjoy your blogs, keep up the good work.

Thanks for your suggestions.

Hi Richard, Helen

Have to agree with the previous comments. A non lathe stool and prep work sound particularly appealing. As to the amateur bit, from the Latin amatorem nom, lover of. If you love what you do, you ‘are’ an amateur whether you get paid for it on not. I am very lucky, I get paid to be an amateur engineer, and fill my own and my family’s homes with items I make. Make with love if not too much skill 🙂

I am an amateur!

See you at the show.

Mark

That’s a nice bit of Latin there Mark! Very interesting to know where the word comes from, thanks.

And that’s another check for a stool then… this seems to be a popular one.

Hi,

I think – only a master could have the courage (guts ?) and the conscience to say what you said above. I fully agree with Mark.

As for me, having the privilege to be an eternal beginner in woodworking , time matters less when doing a project…

I use to tell that to my W_ife :

Wood has three natural enemies :water,wars ….

But I always find in Her a source of demanding projects , a critic all the time and support after completion.

I’m thinking to a steady+low+elegant tea table , made in a good-smelling wood , to drink a cup of tea/coffee with a friend; The table – top should be (janka-hard + warm , flat and wide) -enough and a liiittle -bit higher , to allow drawing on it.

And , of course , well sized three-legged friendly-stools , near it.

But I was just thinking.

No matter what , keep being that amateur.

Thanks Mihai, I think we all need a good critic and support with our woodwork, and who better than your Wife!

I like how you suggest a slightly higher table for drawing at. I think I’d find this much more useful than the usual low down coffee tables. I’m with you on the stool as well, there’s something very appealing about three legs rather than four.

Maybe a small country table, assembled with drawbored joints between the skirt and legs? I’m thinking of a scale that could be tweaked to become a coffee table, TV stand or hall bench -the style of farm table that has wedged through tenon stretchers across the width and a longer, lap-dovetailed stretcher between those. The legs could be resawn from the edges of wider construction lumber.

Thanks Paul, another great suggestion. A smallish table like this would be a good for getting a lot of techniques in to a relatively compact piece of furniture.

It’ll be a toss up for what comes first but we’re getting a nice list of ideas here.

I also like the idea of a stool for the workbench.

Recently I’ve been toying with the idea of making a Japanese style box (typically described as tool boxes). A small one. But that might be an odd project for The English Woodworker 😉

Hi Marty, I’ve never really given Japenese tools a try but their woodworking is fantastic so it’s certainly an interesting thought. I’ve seen that a lot of these boxes have sliding lids and I really like when a design allows the wood and the joinery to do all of the work!

When I retire I might give Japanese woodworking a try 😉

A stool made with joints would be a fantastic project. Sometimes though you can be spoilt for choice. I always like watching this video of a stool being made. all hand tools… http://www.youtube.com/watch?v=3A2G2AAxO98

Loving your work Richard and Helen.

Regards

David

Thanks for the link David, I always find it fascinating to see woodwork being done off the floor! As I’ve just said to Marty I’ve always found Japanese woodworking interesting but unfortunately have never had the time to give it a go. Plus once I got down on the floor you’d need some sort of Japanese crane to get me back up again!

Hi Richard and Helen, I am hoping to retire in the next year or so, so I am assembling a tool set and space in my garage ready to woodwork more when time arrives.

There are a couple of projects I have considered having a go at:- one is a small cupboard built by Cath Fernie from some HMS victory timber, http://barrylowis.co.uk/image/44876889397

and the other is a chest made for Archbald Knox – the great art noveau ‘Liberty’s’ designer http://barrylowis.co.uk/image/45773491044

It would be great to follow you doing one of these projects or something similar. The pictures are from my Tumbler woodworking blog http://www.barrylowis.co.uk.

Keep up the good work – it’s very enjoyable to follow your stories.

Thanks Barry, you’re gathering a nice collection of designs there. I particularly like the Noveau chest, its very unusual but looks incredibly useful as a piece of furniture.

How about a pigeon-hole storage rack for screws, nails and bolts etc. You’d get plenty of use out of your hand-router with all the housings, and cross-halving joints. If you made it two feet square, and about two inches deep, withsay 16 square compartments, a pastel artist would snatch your hand off!

Keep at it.

Says me, who is buying more machines because I am running out of years! 🙂

John

I find that I can never have enough storage in the workshop so this certainly sounds like something I’d find useful!

There’s nothing wrong with buying machines!

I don’t know that this would require a video but I would like some more info and close up pics of your wall mounted plane rack with the arched front.

Keep up the great work with your site. I just watched parts 1 & 2 of the cabinet series. The way you sized that panel with a hatchet was so simple but genius at the same time.

Bill

Hi Richard,

I thought of a good hand tool only project. On October 18, 2012 you did a blog on the little john bench. You also had a tool tote in various stages of being made in that same post. I have made about 20 of them so far. I did my sides with rabbets and a groove in them and the end panels for the bottom. I especially like the dovetail detail for attaching the handle. This tote was one of my first all hand tool made projects. I think that would make a good candidate for a next project.

Hi Richard.

Like some of the comments above, a video on prepping and thicknessing boards would be really good. I think it was on the video you did about the tail vice that you thicknessed a bard using 3 wooden planes. You marked the thickness with a gauge, planed a bevel down to the line at the sides, and then flattened the “roof” in the middle.

Some expansion of this with top tips would be great for those of us without machines, especially as it is such a core skill.

Thanks. Rod