I am now fully committed to using a wooden screw in this workbench but oh… the temptation! I had Mr Arnold’s beautiful old metal screw looking at me from across the workshop as I started to assemble the bench this morning, so I just had to poke it in! I’m very much looking forward to telling you the plans I do have for this lovely screw, which are now coming together ready for down the line.

I am now fully committed to using a wooden screw in this workbench but oh… the temptation! I had Mr Arnold’s beautiful old metal screw looking at me from across the workshop as I started to assemble the bench this morning, so I just had to poke it in! I’m very much looking forward to telling you the plans I do have for this lovely screw, which are now coming together ready for down the line.

As for this bench, I’ve just got the bearers and top to go and then I’ll be on the home run. I should have a full post on tomorrow all about it.

![Simple Work Holding For Ploughing Grooves [Without a Tail Vice]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/07/workholding-without-tail-vice-copy.jpg)

![Gluing Up A Workbench Leg [VIDEO]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/06/gluing-up-a-workbench-leg-video.jpg)

Bench is looking great Richard. HaHa I can see why you are tempted buddy, beautiful old vise 😉

How does it feel to be the envy of the woodworking world, Richard? Who among us wouldn’t want a bench the size of a regulation bowling alley? – :0)

I can see your dilemma with the vise, though. While that is a beautiful, old vise, my opinion is that the ones you make are far prettier.

Just as an aside, is it possible to have your “click to enlarge” images larger? I’m not complaining here. I would just like to see your work a little better. The standard size of your images are 591 pixels wide (yes, I know, who measures these things?), while to show them in all their glory, they should be a minimum of 800. Just asking.

Hi Mitchell,

Are you using Chrome? When I click on the pictures, they are nearly full page, then if I want further magnification, I can go up to “View” on the toolbar and click on Zoom in. If you zoom in about 4 times, just the vise itself will be nearly full screen. HTHs

Mike

Thanks for the comment, Mike, and yes, I do use Chrome now that Safari is knackered.

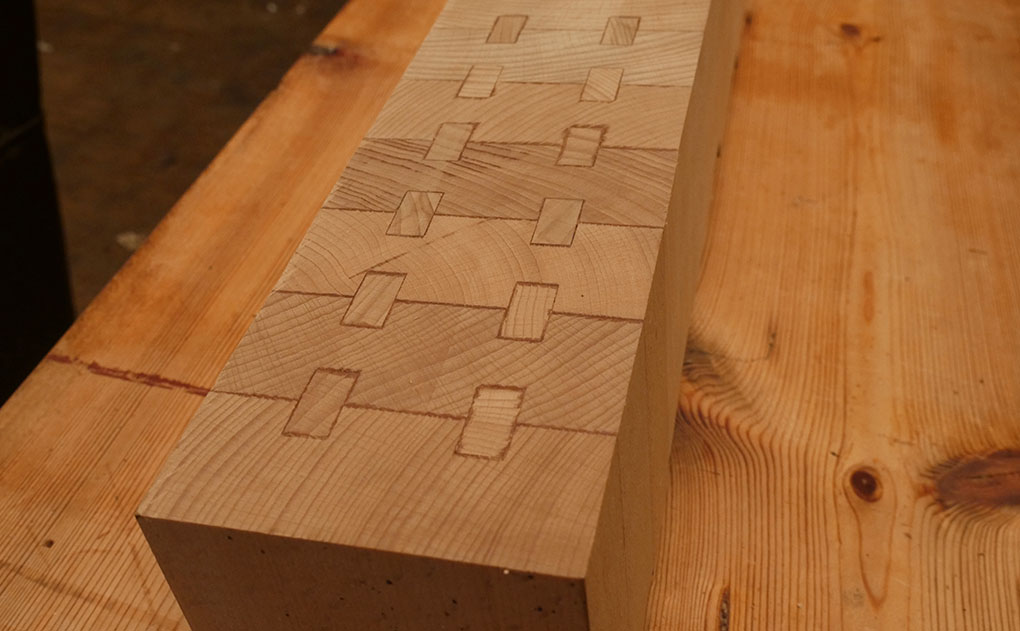

The problem with zooming in, even 4X, is that the image starts to loose its sharpness and begins to pixilate. In the particular case that caused me to comment, I had never seen angled leg supports on an English-styled workbench and I wanted to see how Richard let them into the legs. I couldn’t quite make out the detail in the images at their native sizes and when I zoomed in, the images went soft and the detail was even less.

I’m not being a smart arse here as I appreciate you taking the time to respond to my comment, but a faster way to zoom in is by holding down your Control key (PC) or Command key (Mac) and hit the Plus key to zoom in or the Minus key to zoom out.

Cheers, Mike.

the bench is looking totally bomb proof! Gonna be a great working surface. I have a question about the wood you used. It looks like Norwegian Fir, is that right? Also, is the 2x lumber over there actually 2 inches thick? Our 2x over here is either 1 1/2 or 1 1/4, depending on where you get it.

i was wondering, do you know when you will be able to do anymore video’s, i sure did enjoy the ones you did, and am looking forward to seeing your new place…

It’s late evening here where I’m at and I just found time to sit for a few minutes and study the joinery you have used on the legs for your new bench. Wow, I don’t know how you make it all come together like that. I don’t even know what compound or multiple angle cut-in joints like those are called. You’re good, there’s no doubt of that. I suppose the type of joint you chose also gives strength to the legs besides adding a lot to the aesthetics. I’m impressed. Nice work.

Looks fantastic Richard. I’ve always loved the Nicholson style ever since I saw them many years ago at Colonial Williamsburg’s Anthony Hay Shop. I have a version of it in my shop sitting under some good size double windows for lots of natural light. Mine has a wooden threads twin screw vice but looking at this thread make me want to build another with the more traditional vise and the larger wooden screw.

Thank you so much for doing this blog. It’s become one of my favorites that I always look forward to.

Take Care,

Jamie Bacon