Now and again Richard likes to build a bench that is a little different to what he’s done before to keep himself challenged (like it isn’t difficult enough!) On his current build the motto has been ‘bigger is definitely better!’ Since all of the benches that we build are pretty robust in size this one is to be quite a monster.

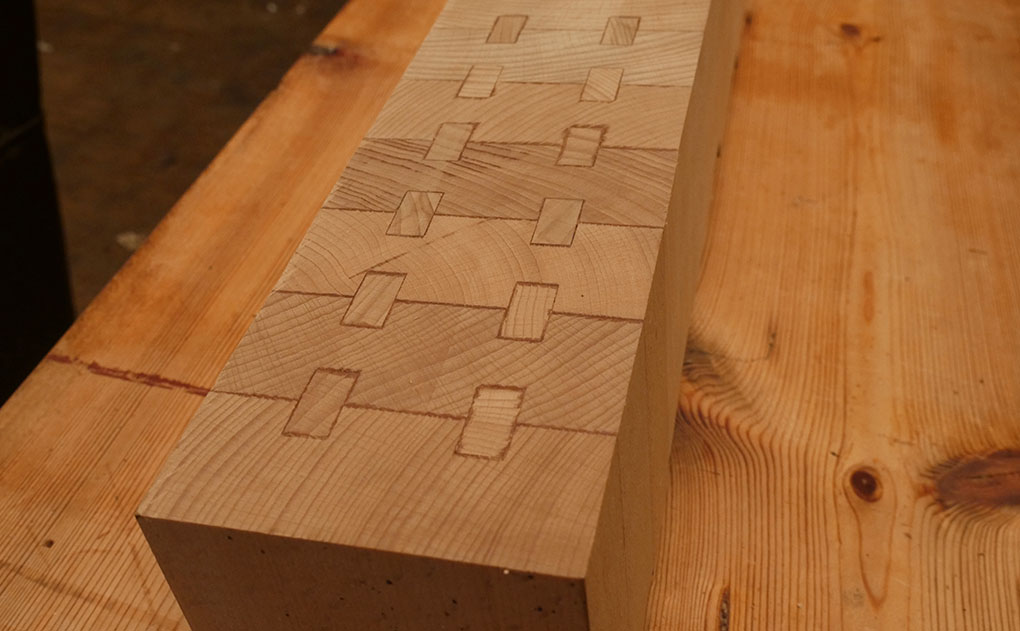

As with most stocky workbenches the design is French in origin which can be fairly simple in appearance so Richard has added a few unusual variations to keep himself content. Right from the start this build has really pushed him, mainly because of the enormous weight of the timbers he’s having to haul around! He made the complicated dovetailed edge on the long rails and wedged through tenons look like a doddle to cut and fit but they caused him a few sleepless nights prior. He knew he’d be plagued by any gaps in those joints but fortunately everything pulled up nice and tight as it should.

Update: At the present time we’re not making any workbenches for sale, however we have many resources on this website that will help guide you with your own workbench build.

Our English Workbench Video Series takes you step by step through a traditional bench build, starting out with a discussion on choosing the ideal dimensions, demonstrations of how to cut the joinery, right through to flattening your workbench top and building the face vice from scratch.

If you’d like us to guide you through your build with detailed videos and PDF plans, then you can find full details for this Workbench Series here.

We produced a special hand wheel leg vice for this bench. We’ve made a couple of these in the past and they’re a rather elaborate mix of a solid bronze nut and hefty 10” diameter cast iron wheel so they spin with some momentum! It’s a nice opportunity on a bench like this to push the vice hardware to see just how good we can get them by using the very best materials and spending time to fettle for the absolute perfect result. The hand wheel has been aged to match our wagon vice and was teamed with our Shaft System to make the leg vice pin less. This combination of hand wheel and Shaft works incredibly well together and because Richard has both made and installed the vice himself it allowed him to tweak and adjust every last tolerance to produce an action that wouldn’t normally be possible on an off the shelf vice. The jaw breezes open without even a whisper of noise or wobble and yet it moves so quickly, it’s quite surreal to watch. Please note we don’t produce these hand wheel vices for individual sale only for installation on our own workbenches. The idea for the hand wheel leg vice comes from Benchcrafted in America so if you’re after something similar they’re definitely worth a look.

As you can see the bench is not quite complete just yet but it should be finished by Sunday night and I’m very much looking forward to seeing it all done.

![Simple Work Holding For Ploughing Grooves [Without a Tail Vice]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/07/workholding-without-tail-vice-copy.jpg)

![Gluing Up A Workbench Leg [VIDEO]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/06/gluing-up-a-workbench-leg-video.jpg)

When dealing with such large material sections do you find that you have to use timbers originally produced for structural purposes?

Hi there, we find ourselves scouring the country for old but unused beams so that we generally have something to hand for when we’re building a large bench such as this. The top and many smaller parts of this bench for example were ripped from an extremely large English pippy oak beam. We found the beam some time ago and it had been sat in a barn for the last half century without any use. I think it was originally 16″ x 14 1/2″ in section x 14′ long! Once ripped it was left for a considerable amount of time for further movement to occur. It isn’t an easy bench to source timber for and can involve a lot of planning in advance! Yes, to a point most of the timbers used would have originally been produced for structural use but they would have been left for a good many years by the time we build with them.

Regards, Helen

I could do with a structural beam… to replace my withering spine 😉

Lovely looking bench so far. I particularly like the massive but plain vice chop and the hardware.

Waiting for four Teardrop handles to complete a TV stand for our daughter in Oak I’ve decided I must build myself

another bench,because this bench can not produce dovetails.

I’m quite astonished really at the way it was so impossible to cut away the waste on these dovetails causing me in my

frustration to walk to our garden wall and place down some MDF and proceed with success, on my strong bench each

blow from my mallet caused all on my bench to dance everywhere so this is my next project and I’m Eighty years old

in two days time.

Yor bench looks as though it will cope very easilly with everything, is a drawing on sale.?.

These legs are massive and must absorb the shocks I spoke about so as stated your bench shows to me at least

that I need such a bench of this type ,planing wood as with many bench jobs is no problem but making things like we

do with dovetails proved a bench of this type to be a must have.

6, Denwick- view, West – acres , Alnwick . Northumberland. NE 66. 2PZ

How much would this bench cost?…I love it. Great work.

That Half-Shouldered, Through-Wedged Half-Dovetail? that you use to join the lower rails to the legs of your bench. Is there a reference you can point me to on how to mark those out??? I’d like to do that on my bench which is probably out of reach for a beginner but if you don’t stretch yourself you don’t learn.