Finally… after taking a bit of a handful on, I’ve now got my old workbench ready for sale.

Most of you will know this bench well. It’s been used in most of the videos and has also been the bench that I built 99% of Maguire Workbenches on. It’s the bench that built benches.

I first designed this workbench to be a nice back to basics thing.

It was when everyone first started wanting bling on every corner of their benches. I wanted to try and make a point that the best benches had less, but what they did have was well thought out and worked.

I never intended for this bench to be mine. It was a prototype and I just ended up using it for a bit, and that bit turned into about seven or eight years. Over this time I’ve become very fond of it, like my hand plane, it’s my old friend.

Sadly though (well it’s not sad really), I need to move forward, and I do like a good change. So the bench needs a new home.

I will say now though, if you buy this bench, I wanna know if you ever want to sell it again.

The bench works as a standard English type workbench… the best type.

Although it is built differently. The base is made of two trestles and the top and aprons are as one. Unusually for an English bench, this means it can be knocked down.

The workbench is 7 ft long, 2 ft wide and 34 inch tall. (2.1m x 600mm x 860mm)

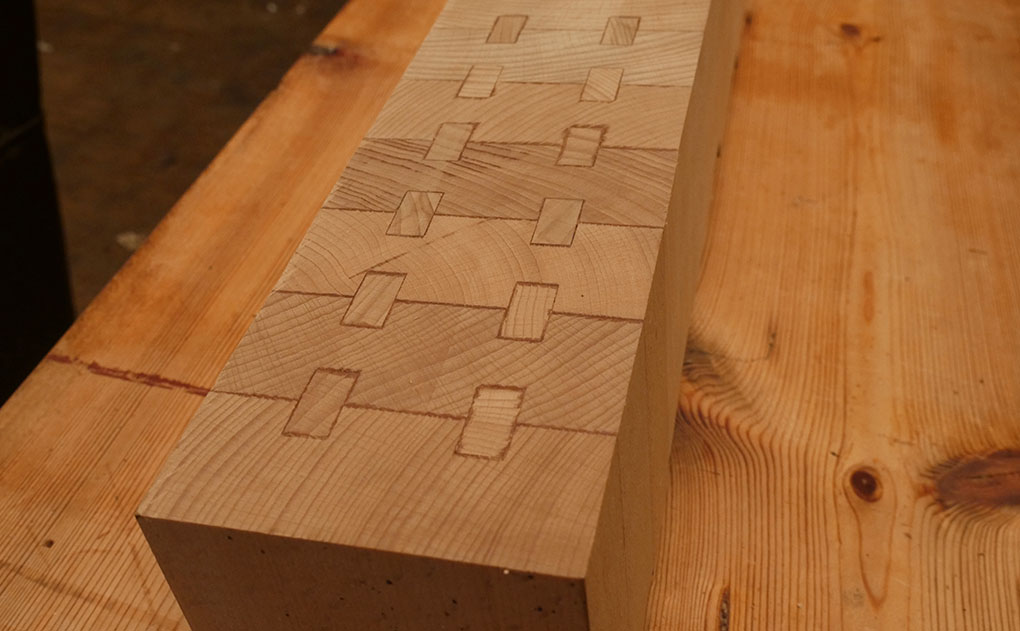

The top is 3 inch (76mm) thick and the whole thing is solid ash.

For work holding it has a lovely broken in face vice with wooden screw, which is fully adjustable for ware.

It has a spiked planing stop, holdfast and dog holes. And a central full length stop.

The bench functions as new with no faults or quirks. It shows its past with its scars, as you can see in the photos.

I’ve given it a full service, so that’s a complete refinish, going over the vice to tune it up, and re-flattened the top.

My aim when building workbenches was to make the finest benches in the world.

This bench in my opinion is the finest bench in the world.

I’m looking for offers around £2300. UK only, and I will be personally delivering this one.

If you would like further details or might be interested in this workbench then please get in touch at richard@theenglishwoodworker.com

![Simple Work Holding For Ploughing Grooves [Without a Tail Vice]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/07/workholding-without-tail-vice-copy.jpg)

![Gluing Up A Workbench Leg [VIDEO]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/06/gluing-up-a-workbench-leg-video.jpg)

can you deliver to US?

What a great offer. Unfortunately out of my budget and I made my own bench to which I have huge emotional attachment because it literally bears my blood and sweat! Whoever is lucky enough to buy this bench will have not only a beautiful thing but also have bought some of your journey as the English Woodworker. Fabulous.

Damn. Shipping to Oregon is probably prohibitive, eh?

I love the English and plan on making one 8 or 9 ft long. The vice I want to copy is your vice however, $600 for a turn screw is way out of my league. The largest threadbox available on the market is 1 1/2″ and many say that not thick enough. They say the diameter should be minimum 2″. Could I get away with 1 1/2″ dia. wooden screw?

Lake Erie Toolworks USA makes an outstanding 2.5 inch Diameter, hard Maple wooden screw and wooden nut. Have one on my Moravian Workbench. Excellent quality. They make other screws too.

https://www.lakeerietoolworks.com/

Michael O’Brien

Alabama, USA

I’ve seen this lovely bench in a lot of your blog posts and videos over the years. Just out of curiosity, does it have the usual bearers running between the aprons to support the top? I’d imagine a 3″-thick top wouldn’t need them.

Wow what a deal, and solid ash. If I lived in UK, i’d grab it, even though i already made one from your plans, but its pretty soft alder.

Good evening Helen and Richard

Just wondered if the two of you have or are planning more on line videos as I haven’t heard anything from you for a little while.

Yours faithfully

ross

Well, if it weren’t for the Brexit, now would be a good time to migrate into England…

Richard and Helen

Would love to find room for this lovely bench to complement the other bench you built for me but alas I cannot find room for it. It will make someone very happy to have this splendid bench and for you to set it up for them in the same way as you hand delivered and commissioned mine.

Good luck and very much look forward to more project videos and blogs.

Len

Richard and Helen

Thanks very much for the offer Richard, but I’ve made my

own having watched the video work shop the you sent me

some time ago. And I’am very happy with it and glad that I

did as I did learn so much more from what you tought me.

As I’am currently in the proccess of make (when I get the

spaire time that is) our new Cheery top dinning table which

is my take on the one you showed us all how to make.

Regards,

Pete Maddock

I’m curious as to what you are replacing it with?

I believe this is what he made the French Workbench for, something that fits a little better on camera.