Our latest small woodworking bench has now been named and is ready to step out in to the big bad world. We introduced The ‘Little John’ last month and if you haven’t seen it yet you can catch up with that post here. After taking this compact 5′ workbench along to the European Woodworking Show we’re confident that the design is right and offers everything that we’d hoped for in such a tiny hand tool workbench. His rock solid stance under planing definitely impressed!

Update: At the present time we’re not making any workbenches for sale, however we have many resources available on this website that will help guide you with your own workbench build.

You can also check out our Video Series which teaches you step by step How to Build A Workbench (includes PDF plans).

This build is based on a traditional English workbench design, which can be scaled for both a large or small workbench.

Along with the build we go through a discussion on choosing your ideal workbench dimensions (height, width & length).

This is the ideal workbench to build with just simple hand tools, and we demonstrate everything from how to cut the joinery right through to flattening your workbench top, and building a traditional face vice from scratch.

Find full details of this video build – Building A Traditional English Workbench – with PDF plans.

Unlike our other traditional workbenches The Little John has been designed for us to build in small batches and the first ones will be built in February. We’ve started taking deposits for benches within this limited batch and if you’re interested please feel free to send us an email.

We found the perfect tail vice for this bench in the Veritas inset vice. This is very compact and unobtrusive but works much like a wagon vice with a moving plate to allow work to be clamped down to the bench top between dogs. It holds extremely well and whilst we had a small issue with it to begin with we’ve since spoken to the chaps at Veritas and will explain once the amendment arrives.

For the face vice we opted for a traditional leg vice with parallel guide and steel thread. From what we can see it isn’t easy to find a small workbench for sale that won’t wobble about and move whilst you work, so we made strength and stability amongst our main priorities. The vices and work holding were the other priority and this pair of vices together with the ¾” dog holes offer all of the strength and versatility that you will need from a traditional bench.

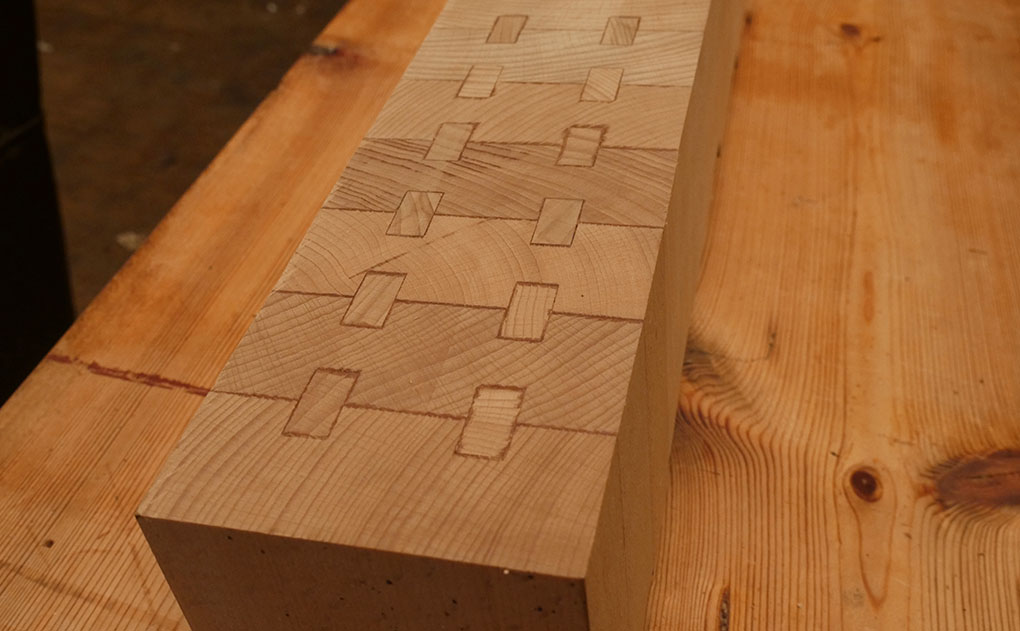

Providing a thick, heavy top is key to a good hand tool workbench. This one is 68mm thick so you have all the weight and support where you need it with a tool well for tools at the back. Two trays in the well can easily be removed for cleaning and can also be sat up on supports to bring them in line with the bench top – a useful feature if you need to stand say a chair on top of the workbench without the back legs falling in to the well.

This workbench has been used and abused in our workshop daily since it was built, and Richard won’t be parting with his prototype! I’ll try to get some video footage on here next week to show you what we mean by rock solid: Watch The Little John Workbench In Use

Building Your Own Traditional Workbench?

Check out these posts for more information to help with your build.

– Choosing The Best Wood When Building A Workbench

– Why You Only Need ONE Woodworking Vice

– Master Traditional Workholding – Your Guide To Woodworking With Holdfasts

– Pick The Best Face Vice For Your Workbench

![Simple Work Holding For Ploughing Grooves [Without a Tail Vice]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/07/workholding-without-tail-vice-copy.jpg)

![Gluing Up A Workbench Leg [VIDEO]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/06/gluing-up-a-workbench-leg-video.jpg)

Lovely looking bench.

Richard better get well rested as I think he’s going to be very busy.

Thanks Patrick. Did you hear that Helen…’well rested’. Does that mean I can have the weekend off?! 😉

Hi Helen,

I’ve never seen a plane stood on its toe as shown in your pictures. Can you talk about why you stand it up that way?

Chris

Hi Chris,

It’s always been drilled in to me to put a plane down on its side and not its sole. With the coffin shaped smoother though it doesn’t sit on its side well due to the curves and rather than just throwing it on to its sole constantly I sit it like this instead. It’s more of a habit and seems very natural to me so I don’t even know I’m doing it. When I’m working I do also make minor adjustments to the depth of cut by tapping either the toe or heel on the top of the bench.

P.s some lovely work on your site 🙂

Richard.

Hi Richard,

It’s nice to find another woodworker who adjusts wooden planes without tools. I think that one corner of my bench is denser than the rest from hitting plane blades against it.

Thank you for the comment on my work.

Chris

Great bench, proves you don’t need a behemoth to do good work. I especially like the supporting frame construction.

Hi, I’m actually in the process of building a bench quite similar to this one, and I happened to come across this here recently.

I was trying to think of a good way to get a [more] traditional wagon vise on mine, but was also contemplating the Veritas inset wagon as you’ve demonstrated here.

I was curious, however, that you wrote “and whilst we had a small issue with it to begin with we’ve since spoken to the chaps at Veritas and will explain once the amendment arrives.”

Might I inquire as to what the issue was? Or is it posted somewhere I’ve missed?

Thanks!

Hi Chris, Many thanks for the reminder on this! I’ve just posted the info that you’re looking for I hope this helps https://www.theenglishwoodworker.com/?p=617

Thanks! I just finished reading it, and it was pretty much what I expected. That was my main concern about it as well. Thanks!

Very nice!

Your Little John looks like a refined version of Charles H. Hayward’s bench, (complete with canted legs and similar proportions), variations of which appear in several of his books. Here’s one example from his HOW TO MAKE WOODWORK TOOLS book (page 1):

http://toolemera.com/bkpdf/haywardhowtobk.pdf

Scott,

Thanks for the attachment. I have been working with wood for 8 years but only recently started working with just hand tools. I have been watching videos to get the basic idea but sometimes the instructions are lacking and your attachment is just what i was looking for to make my own tools and not buy.

What is the height of the bench? I’m 5’-11” tall and work with hand tools. Mostly sawing, brace hole boring ( not that often), hand planing and sanding. Looking for suggestions on height.