We’re Building A Great Big Dining Table, Entirely by Hand… In a Tiny Space!

The weekly videos will kick off on 11th Feb, and take you step-by-step through the build of this traditional, sizable trestle table (Watch the intro above).

The series can be purchased at the intro price by Clicking Here

If you’re already a Member then you may need to Login first

In our latest series, we’re returning to tradition.

Not only in the design of the table, but also in the approach.

We’re building in a very restricted workspace this time, so it seemed about right to build the biggest piece of furniture we’ve done to date!

That’s not just because I like to struggle, it’s to make the point that when you’re working solely with hand tools, just how little space you actually need.

We bring the tools to the work. There’s no need to allow for feeding things in and out.

The Trestle Table Design

The trestle table is a very old design.

It depends on stout trestles being able to bear the load of the top. These are connected here with a central rail, which makes it an ideal design if you’re looking for something to knock-down and transport.

The rail is locked in place with wedges through the tusk tenons, and can simple knock out again to dismantle.

Arranging the base in this way makes it a great choice as a dining table, as there’s plenty of clearance for legs. And it’s also a very easy design to adapt to suit different dimensions and spaces.

Whilst the layout is traditional, I did opt to give it a modern crispness by avoiding anything overly ornate.

Each trestle is like an I-beam, but every face of the components has been selectively tapered to give subtle facets, and lightness towards the top.

The Hand Tools

We’ve gone back to basics with the tool kit, and built the entire piece start to finish by hand.

There’s no reason you couldn’t opt to prep on machines. But it is a great build to get in some planing practice, and the videos go through step by step the specific approach for doing it the hand tool way.

It’s a big build and since there’s nothing fancy involved (no specialist planes or anything like that), it seems worth noting that sharp tools are the key. A well set plane and keeping a sharp edge on your chisels is all that’s really important.

The tool kit itself can be incredibly minimal:

- The usual marking & measuring tools.

- Saws. A hardpoint saw was used for all the cuts throughout.

- Bench Planes. A jack and optionally a jointer & smoother. (Different irons are required for roughing & smoothing).

- Chisels. Strong bevel edge of morticing, plus one sharpened for paring.

- Mallet | Drill (I opted for electric) | Shooting board | Clamps

The Techniques

Building the trestle table is a workout of hand tool fundamentals.

We go through how to prep these large boards by hand efficiently. And that includes everything from understanding twist to edge jointing for the perfect glue line.

The top boards are also held together with loose tenons, and finished off with end caps and a tapered underside.

Hefty mortice and tenons and used for the trestles and centre rail. There’s some variation from usual as we tackle joining in to the angled faces, locking the joints with wedges, and perfecting those extremely long tusk tenons of the rail that have a wedge morticed through and tenon cheeks that are on show.

There’s a lot covered in this build, in fact it looks set to be one of the longest series we’ve produced.

See here for more details of what you’ll find in each of the videos.

The Videos

We’re looking at breaking it in to ten chapters in total.

Chapter One will be live on Thursday 11th February.

Followed by a new video each week to stream and/ or download.

A cutting list and full PDF plans will also be included.

The series can be purchased at the intro price by Clicking Here

If you’re already a Member then you may need to Login first

For further details on what’s covered in each of the videos, have a look here.

Not familiar with our Videos?

We make online courses that provide tuition on hand tool woodworking.

The detailed videos can be both streamed and downloaded.

As a professional hand tool woodworker, we aim to get you feeling inspired to build, and equipped with the knowledge to tackle projects entirely by hand.

View our full Collection of Video Series HERE

Or sign up to our Free Plane Build Mini Series HERE

Bloody hell I am excited about this! New workshop and no power? I am sure there’s a story there.

*throws cash immediately*

I can hardly wait for the first installment! I grew up sitting around a dining room table just like this one. It was made of southern yellow pine and had ladder back chairs. Mom and Dad had it until they passed.

He lives! The prodigal son has returned. Hadn’t seen anything here or on Winglewood new for some time and thought you guys fell off the map. Cheers!

Back to the basics — I love it and am looking forward to this series.

So happy to see you are back! The table looks amazing, minimalistic with beautiful details and, as usual, outstanding craftsmanship. Looking forward to the series!

Another great series by the looks of the intro…cant wait! Hope your going to give a few posts on the blog? New workshop?

So pleased to see another video series. Kept coming back to the website to see what you’d be making next.

Great timing! I am just fitting the joints on a new sawbench that will be delighted to have its first job lined up.

Bravo and welcome back with a bang! This looks like a super table!

For me, this is the most interesting build you have filmed in a while. It comes in a time where I need to build myself a dinner table. I am definitely going to build this one!

Well Sir, I thought this was an imposter what with the new music and all. Then I saw someone that sounded like you but… you cleaned up like a GC model! What gives?

Yes!!! I’ve wondering when I would see this pop up in me inbox, a no it’s only February but it’s the best email I’ve had this year !

A can’t wait and it looks like it’s going to be a cracking one as well , lookout oil stone here I come !

Whjy is the bevel edge on the upper surface of the table top rather than underneath?

John, i think you are just seeing him prep the bevel up for ease, but later it is flipped down for assembly. Zoom in on the finished table at the end.

hello you two,

this is another series just to my liking. 🙂

I would like it even better if you had chosen sliding dovetails for the connection to the tabletop.

I would have liked to see how your approach is.

In this case the connection would have fitted perfectly with this design.

Maybe you’ll do a bonus episode? 😉

A bonus episode with a sliding dovetail connection would be awesome.

Dang!

I’m really excited to see this, but I have just started building one, sort of a compromise between the Shaker table presented by Roy Underhill a few decades back and some Japanese guy (Ishtani furniture or somesuch). Top and bottom rail joinery for one trestle is cut already (not traditional mortise and tennon, but an open mortise I guess it is called). I will be draw bored, or so I plan.

Still, I’m excited to see what I can learn and adapt from this project!

I’m thinking to make a table in this style for ( ? ) years….It will be in plane tree…So I bought this serie without checking the intro.

hi there,

there is any roadmap of futures videos? 🙂

ps: your videos are a blast, and you english make me feel sad that i left UK for germany 🙂

i have another comment here after I’ve watch more videos. You are a young and funny paul sellers 😀

Yippee – another wonderful project from you guys – you da bomb! Totally love your down to earth commentaries, the clean nature of your presentations and the perfect music. So very happy to support this business as no-one else comes close to what you offer. Thanks guys!!

I have to agree. The videos are clean and crisp and the explanations are very clear and easy to follow and understand. I think the best parts if I had to choose is his unbelievably thick shavings he makes without breaking a sweat. I know it all comes to sharpness but I sometimes wonder if his timber is really butter and just made to look like timber. Well done Richard and Helen

How did I miss this?? Carrying on…

Super as always.

Question, have lumber prices risen over there? They are 4 to 6 times what they were at the begining of 2021.

not in europe, as here where all the time expensive 🙂

True. 😁

Though lumber prices have increased a lot here too.

Construction lumber

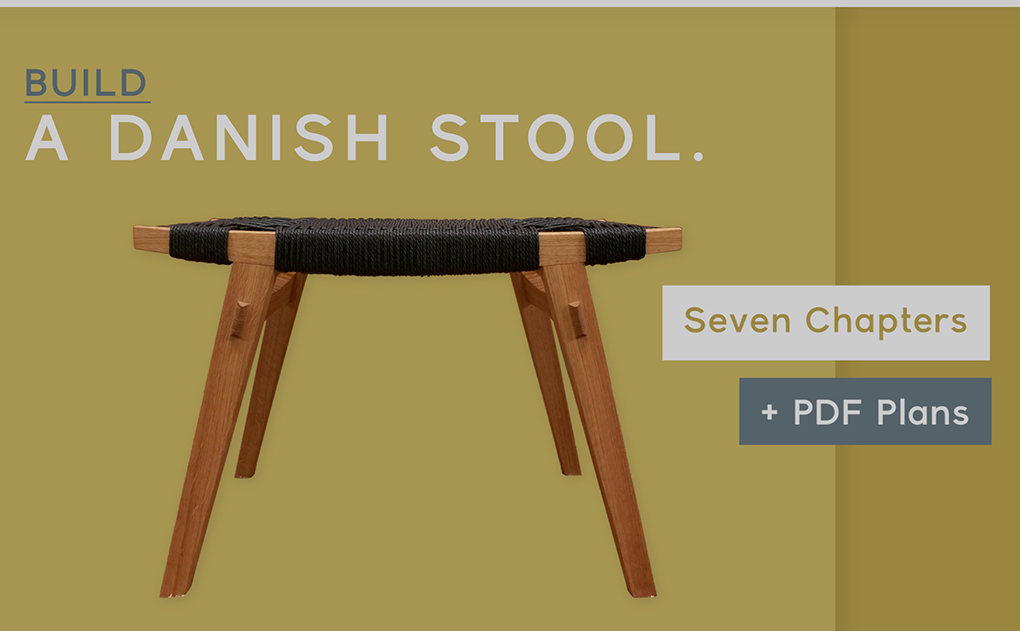

This will indeed be my next, next project after the danish stool. Glad to see you’re back n the game Richard. I’ve been watching a lot of your older videos as of late and I must say I’m very impressed with your workmanship and your use of good but not extravagant tools, as it should be. You can certainly do a lot with a little and add to it later when you can. Please keep up the good work.