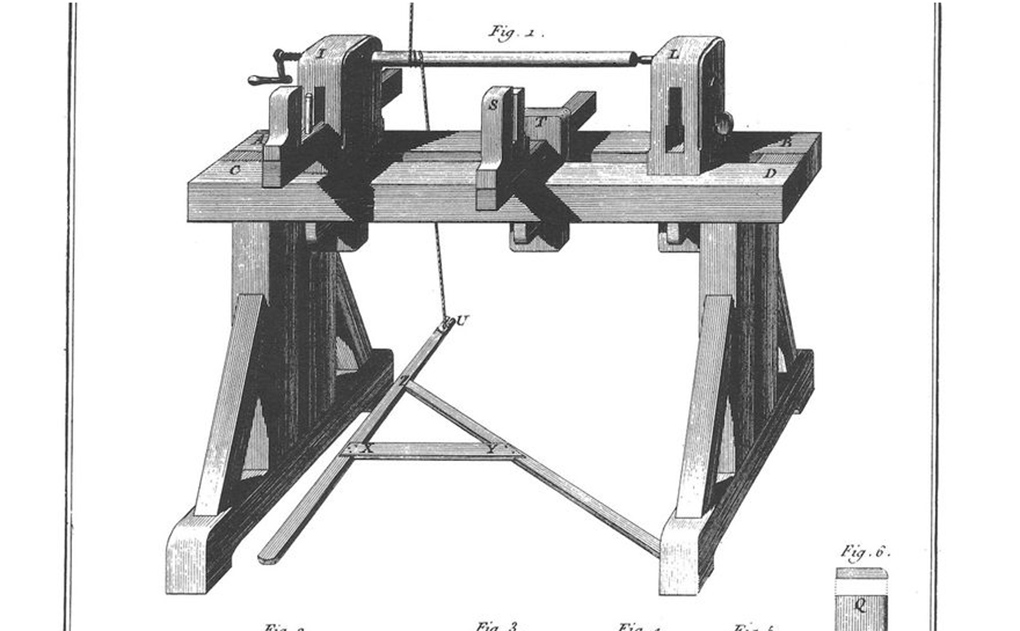

I just popped out and left Richard to get on with building the new table for the cross-cut saw. I got back to find what looked more like a workbench.

This rather sturdy looking table design has been giving him a bit of mental grief for a couple of weeks now as he’s been trying to plan for all eventualities, making sure that it’s both adjustable for accuracy and strong. As a completely seperate unit from the saw there’s little reference to go off so they need to be independantly adjustable to be set up and fine tuned for squareness and accuracy in all directions. Still, it looks like he’s used an awful lot of wood so I hope he’s got it right!

It looks great guys, real nice work

Cheers

Ken 😉

a beauty. It’ll do the cross-saw proud and last as long. I’m expecting an adjustable end-stop at some stage, in the range 5 – 8 feet (accurate to 0.1mm maybe)??

So this is Richard’s idea of offcuts.

Hi Douglas, The table’s now completed so the photos will be up soon. You’ll probably recall that the table in Kent made use of the original Wadkin bar and stops which they’ve managed to salvage so these will be added to it eventually. The bar must be 10′ – 12′ foot long and takes two men to lift (proper Wadkin job!) but for now to get the saw earning its keep we’ve gone for a wooden fence and will use a block and clamp as a stop.