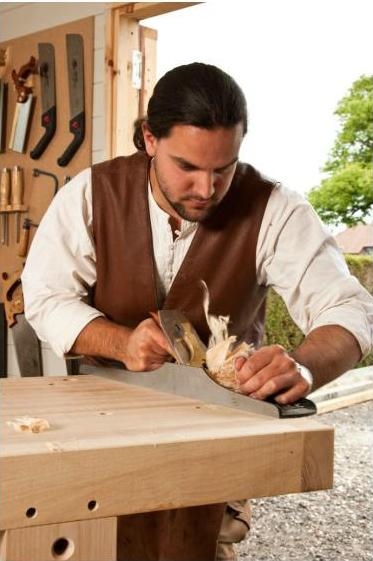

I received an email this morning asking if I feel it’s a good idea to use a toothing plane on a bench top. I was slightly unsure of the intent at first but soon realised that this was a question of roughing up your bench top to increase the friction. Yes absolutely, I think that increasing grip on your top is a great idea although I’ve never gone about it with a toothing plane.

Holding work is one of the main functions of your workbench and we go to great lengths to keep it still with tail vices, bench stop, holdfasts etc. Having a perfectly smooth and waxed bench top works against all of these attempts and whilst it’s prettier and good at repelling glue a nice shiny surface will only help your work to go shooting across the workshop every time your plane looks at it!

I always create extra friction and my method is to simply finish the flattening process with a heavy cross grain pass using a slightly cambered iron. Going across the grain like this creates a surprising amount of texture and roughness to the surface and once finished the top is protected enough to repel spillages of glue but remains nice and ‘grippy’.

I got the idea for this after noticing some obvious tooling marks across the top of an old workbench which suggested it had been finished in a similar manner. I couldn’t say if the technique has ever been widely used as this bench may have been the exception but I liked the theory and decided to give it a try. I felt it had a very positive effect on the bench top and as a bonus its very easy to recreate when the top needs to be re-flattened or cleaned up – I find that unless the top’s moved to some extreme it can be re-flattened at least a couple of times by just taking the cross grain passes.

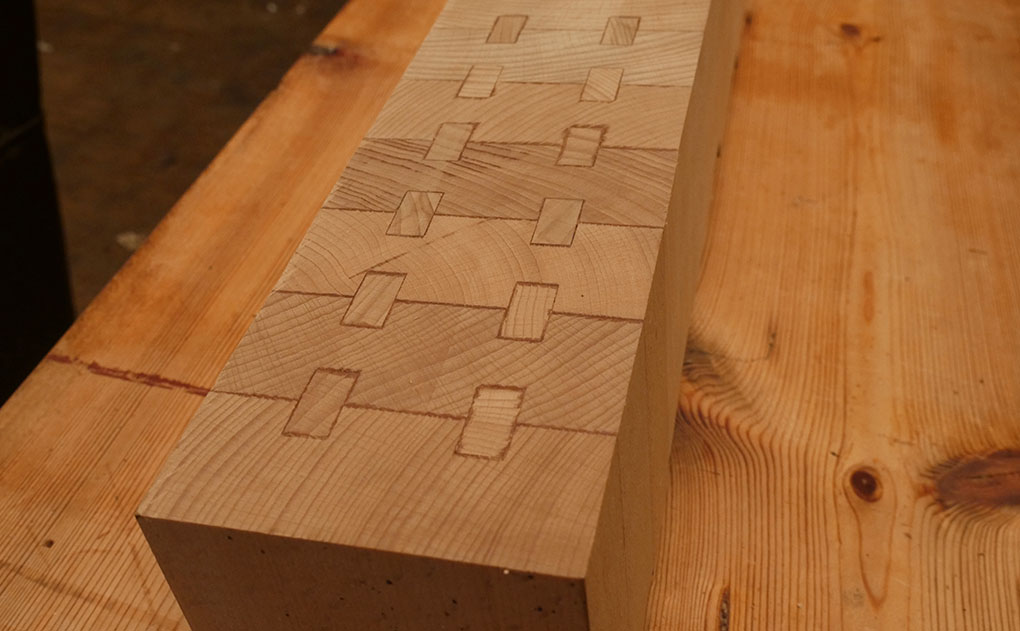

As for a toothing plane, I can imagine this would work very well for roughing things up, even more so than the method I currently use. It would maybe look a little odd though and my concern would be that the ridges would make for rather quick and uneven wear over the surface leading to a more frequent need to flatten. Mostly though I find it hard to imagine how you could clean up spillages or tiny fillings with any ease (I tend to sharpen saws at my workbench). I’m always wiping glue and finishes off my bench top and this would be pretty awkward if it’s embedded in ridges. I expect a toothing plane would give a perfectly rough surface but perhaps the benefits could be short lived.

The result from my method isn’t so obvious but I feel it gives all of the texture needed and I know that it’s made a difference because often a customer will enquire to why they’re bench top isn’t as smooth as the rest. If you’re looking to add friction then my recommendation would be to cross grain plane it – this gives a great result without any real negatives.

It would of course be interesting to hear if anyone has used a toothing plane and if so how do you find the results? Are any other top roughening methods out there or do you even feel its necessary to take this extra step?

![Simple Work Holding For Ploughing Grooves [Without a Tail Vice]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/07/workholding-without-tail-vice-copy.jpg)

![Gluing Up A Workbench Leg [VIDEO]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/06/gluing-up-a-workbench-leg-video.jpg)

Hi Richard,

Having not long finished my ‘Roubo’ style bench and taken great pains to ensure the top is flat and smooth, I can’t bring myself to ‘rough it up’!

I guess when I get around to using it in anger I might give in and apply your suggested treatment, but for now I’m happy to just look at it and reflect in the satisfaction I got from making the bench.

PS

I love your wagon vice – I don’t know how I lived without one for the last 40 years of woodworking.

Keep up the great communications.

Ian

Hi Ian,

Just keeping using it for now and in a few more months (+ some blood, tea and shellac) and you should feel more comfortable about tearing up your bench top!

By the way, you did a cracking job of it 🙂

Chris Schwarz has just written a piece about using a toothing plane on his bench top http://blog.lostartpress.com/2013/02/16/toothing-your-benchtop-for-bench-nerds/

I frequently use a toothed blade in a bench plane when preparing boards as it avoids tearout but I’ve not toothed my bench top (it’s made from MDF).

Thanks for the link, I’ll get the kettle on and take a look through that. My questions on bench building often seem to stem from what’s going on in the States!

I remember you mentioning your toothing plane use for preparing boards, it’s something I’m very intrigued to give a whirl when I get time to change my routine.

I learned the technique from Deneb Puchalski when he was at a Classic Hand Tools event at West Dean a few years ago. Here’s a video http://www.youtube.com/watch?v=Gl8Tj1lUha4&list=PL76ED2FC43576D6AF&index=31

I have used a toothed blade in a bevel-down plane until now (you need to set the cap iron a long way back to stop shavings getting trapped) but have recently bought a bevel-up plane so will be trying that soon.

Interesting topic, I know that Chris Schwarz has been an advocate for using a toothing plane on a workbench top. This subject has come up in the past on a woodworking forum I participate in regularly.

I didn’t like the idea of using a toothing plane for some of the rasons you stated, but I never thought about cross-grain planing. I might have to give that a try once I get it completed.

Thanks Mosquito (great name!), if you’re flattening a top anyway then it’s a good time to have a little play. If you’re not keen on the result then you’ll be in the zone anyway to carry on and plane it back out!

Is there any historical reference that states this (toothing or cross-grain planing) was done to new benches and not done later simply to clean off grunge?

There’s no reference that I’m aware of or nothing set in stone at least, like I say I’ve only taken note of the cross grain planing on one example. I opt to do it on my benches because I feel it offers a worthwhile advantage.

Cheers, Richard

http://woodtreks.com/design-build-traditional-woodworking-workbench-tail-shoulder-leg-vises/1651/

Here’s is a furniture restorer in The states (sorry) who talks about using a toothing plane on his bench, amongst other things.

cheers

Martin

I still have my bench top to plane up, so again another great post.

Nice job Richard 😉

I am sure the law of diminishing returns applies here! Why on earth would anybody want to rip the top of a bench to pieces with a toothing plane? Friction is relative to surface area,and if we reduce the surface area by 50% by mutilating the bench top with a toothing plane,it will not only collect all the chips and glue drippings but must surely reduce the friction,just try it by attaching a weight with a cord,then see which top grips the best,if you currugate the top of your bench,you must reduce the surface /friction area,the only exeption is if the workpiece is also corrugated to match! Another American fad I think!

Chris,

France.

I think it’s a solution (or barely so) in search of a problem. While Patrick Edwards (from whom Chris Schwarz got the idea) is a world-class marquetarian, there are plenty of other world-class cabinetmakers who have never advocated such a practice.

I would love to see the look on Frank Klausz’s face if somebody suggested that he tooth the top of his exquisite bench. I think he’s figured out how to process furniture parts without them moving around under tool, and without toothing his bench.

For Edwards, somebody who works constantly with hot hide glue (with need to clean off same) and with small thin parts that defy cramping, holding with dogs, hold-downs, etc. it might make sense. For the rest of us maybe not so much.