I’m not one to talk about safety often because I don’t like to come across as patronising. I noticed recently though just how many cheaply made machines have become available for ‘DIY’ and I thought I’d have a moan – I will try to keep this short and sweet!

I’d seen ‘table saws’ for sale as low as £50. This is the price brand new and not on offer so you can imagine the quality of these pieces. My issue with cheap machines is that they’re flimsy and light weight and in my mind when it comes to spinning blades stability should definitely be high up on the safety check list.

Another issue I feel our safety conscious workshops can overlook is creating the right respect for the power of our machines. Everything about my Wadkin cross cut saw demands respect; it stands proud and industrial and when you put it to work it sounds like an aeroplane starting up. Now, I’m not suggesting we all need huge machines like this – not at all. But this machine puts you in the right zone for working and we do need to give all machines this same respect.

Giving a machine colourful plastic coatings and a manageable weight might make them look less imposing but it doesn’t make them free from hazard. The real danger comes when we become too reliant on a tool’s safety features for keeping us from harm. I saw a programme once which illustrated this well for me:

Amongst other things the programme covered the story from a joiner who used a hand held circular saw on his jobs. His saw had the usual retractable guard which sprung in to place as it was lifted from each cut. For speed the joiner could put his saw straight down on the floor between cuts without having to wait for it to stop spinning. He worked repetitively and this guard kept him safe up until the one time that it got stuck.

Saw went on the floor – saw kicked up off the spinning blade – blade clipped him in the bollocks.

So the moral of the story? Keep up your own guard, no matter how safe a machine might look.

![Simple Work Holding For Ploughing Grooves [Without a Tail Vice]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/07/workholding-without-tail-vice-copy.jpg)

As my old grandad would have said, “that’ll learn him”.

Hi Richard, Your post puts me in mind of several things, firstly the signage that says “this machine has no brain use your own” and also of the the clipped or missing fingers on the hands of the machinists at the Joinery firm my father used to manage. In my experience I find tiredness, rushing or over-confidence to be the enemy. Last year I lost the tip of my little finger putting some timber over the planer, it was my trailing hand and I had my attention in the wrong place I guess. I don’t think it’s essentially about guards (although very important) or the size of machine but some safety forethought and attentiveness. All that said-I too much prefer the build quality and the sheer grounding weight of the older machines! Thanks, Steve.

I totally agree. The only time I was injured was when I was rushing to finish a project and I was tired. I knew better to perform the cutting operation without a proper jig, but I didn’t. I was lucky, I just destroyed the first joint of my first finger of my right hand. It is still there but a little crooked. I was using a 1940’s Delta/Rockwall cabinet Saw I had refurbished. Strange…the saw did not even slow down when got to my finger!

You are you best safety guard!

Wadkin SR Richard? We had one for a while but is was a bit temperamental. Bed goes up and down tool which is very old school. I must say I think big fixed machines like this are safer and I would prefer using one over a hand held tool any day.

I saw that same programme, Richard. Very sobering and, like you, I’ve never forgotten it. Things happen very fast with powered tools.

Hi Richard – good point!

I watch in disbelief on YouTube at some of the methods used when people are power sawing. A quick ‘google’ brought up these stats…

Table saw accidents are painful, life-changing and expensive. Each year, more than 67,000 U.S. workers and do-it-yourselfers suffer blade contact injuries, according to government estimates, including more than 33,000 injuries treated in emergency rooms and 4,000 amputations.

reference…

http://business-ethics.com/2013/05/16/1247-power-saw-injuries-mount-the-case-of-adam-thull/

Be careful out there guys – woodworking and life in general is very difficult with lost digits or worse!

The statistics on power-tool accidents in the US don’t surprise me. In the UK it is illegal under Health and Safety Regulations (they don’t apply to home working for pleasure) to use a circular saw without a properly fitted crown guard and riving knife. Therefore no grooving or rebating, and no use of dado-sets (I believe it’s illegal to even sell them in this country).

Now go and watch any American wood-working channel: if you see a guard and riving knife in one video in a hundred you’ll be lucky. And no disclaimers about “guard removed for clarity” either. One of the most hypocritical in this respect is Norm Abrams with his pious “Always read the instructions blah, blah, blah”.

I know from experience that machines bite. While working as a workshop technician in a local school, I was preparing a large amount of materials for one particular product, cutting 10 x 10mm strips, and in a moment of forgetfulness managed to feed my left index finger into the circular saw with the result it is short of about 10 mm. It’s a constant reminder!

More and more I find myself using handtools when I can get the job done on my tablesaw, router ect. I’m finding it a lot more fun to do it by hand. I also feel a bit more proud of myself when I do it by hand. I blame Richard, Paul Sellers, Shannon Rogers and Rob Cosman for that. A very big THANK YOU to all those guys. Again thanks Richard for what you do. Gary

I spent a summer as a stage carpenter, working with a bunch of apprentices – college theater majors who wanted to be around anything theatrical. The circular saw’s guard had a broken spring, so it had to be returned manually. I harangued the apprentices for a good five minutes about the danger before we got to building the next set piece. After cutting a board to length, I put the saw down on the floor, forgetting my own rant. As soon as the saw hit the stage, it shot backward over my right foot. Fortunately, the pendulum of my arm swung the saw with its spinning blade in an upward arc that allowed it to slice through the leather upper of my shoe but cut no deeper. The apprentices were impressed. So was the technical director, who bought us a new saw.

In my opinion, if you treat any machine like its a hand grenade with the pin pulled out you will be ok.

Amen

You’re so right about the flimsy machines… They are dangerous not only because of the flimsy-ness, but also ’cause more ( inexperienced ) people start using these machines with all possible results.

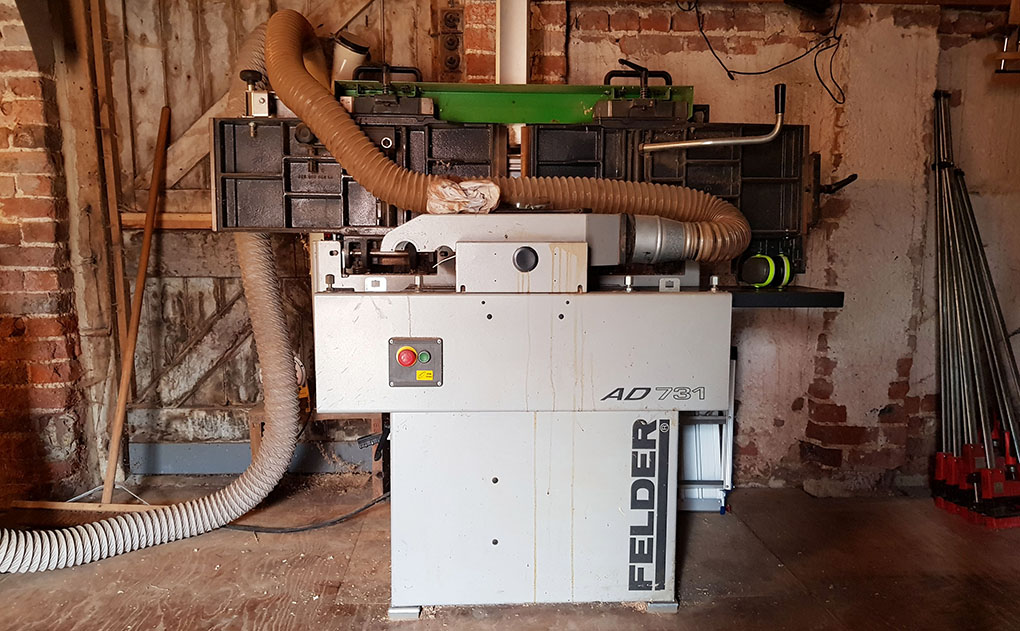

I use Felder machines, mostly for the rough work, but no matter how sturdy en safe they can be; I have the deepest respect for these monsters. Maybe even a bit afraid if I’m honest.

And I try to keep that feeling alive as that will – hopefully – leave me with 10 fingers and no dents in my head!

Good post !

Cheers,

Mac

You will all have heard of the saying “familiarity breeds contempt”.

Well try this out for size.

Some years ago when I was still in charge of stuff, one of my technicians, accompanied with his wife comes into my office with his right arm in a sling and his hand very heavily bandaged. He was sorry he had not been at work for some time as he had been in hospital getting stitched back together.

He had been cleaning his motorcycle in the garage when he decided to grease the chain. So with the bike up on the main stand with the engine running and first gear engaged, he duly sprayed the chain with oil (you can see where this is going). Because he didn’t want to splatter his nice clean bike with all the oil on the chain he thought he would clean off the excess. So with rag in hand he starts to apply pressure to the fast rotating chain and the inevitable happened, the rag caught and his hand was dragged round the chain sprocket duly severing and crushing a goodly number of digits.

The astonishing thing was not just his stupidity for even attempting to beat the laws of physics but the fact that his wife was surprised it had happened at all “because he always cleaned his chain like this”.

We might bang on at our lads on the shop floor about Safety in the Workplace, etc but as soon as they get home their brains seem to migrate to their underpants.

Cheers

Drew

I make Cricket Willow clefts for a living and use a Sagar table saw with 35” blade, powered by a 1936 10hp motor made by Brook of Huddersfield. I was very nervous when I first started using it but over time I have come to appreciate its solidity, predictability and power. As others have said, fatigue and haste are the enemy and I make sure I take a break or slow down whenever I feel my concentration is dipping. I use deliberate repetitive movements and grips that I have drilled into myself, to keep my hands out of harms way and to minimise any chance of me slipping towards the blade. I used to use gloves but no longer do on the grounds that a glove could get sucked in and take my hand and arm with it. The only scary moments I have nowadays are when the tension in the wood is released in such a way that the cleft grabs tight on the blade which can lead to the cleft being launched into my body. I’m pretty good at sensing this before it happens and pulling back now.

I have owned four table saws throughout my life, ranging from the $100-specials to a pro-model cabinet saw. As with everything manufactured, the newer the model, the less stability in its construction. I switched to hand tools ten years ago due to loosing my eyesight, but I still keep up with what is available. To date, the best table saw I have seen is the one my old man had; a 1949 8″ Beaver CS3200 Bench Saw. It was a semi-steel cast boat-anchor with a 22″ square table that weighed 147-pounds without its ½ h.p. motor. He used to haul it around to his job-sites in the trunk of his car. That so-called “portable” table saw was probably one of the most accurate and stable saws ever made.

It’s quite scary that completely untutored people can buy and use machines – especially the cheap ones as you say. I had a cheap mitre saw once, and one of its features was that the rod supporting the length-stop could foul the back of the blade if it were set very short. I found out from the high-pitched screech of metal on metal and the scattering of (fortunately tiny) wounds on my hand where the fragments of TCT had landed. Luckily I was wearing face protection or it could have been a lot worse.

I use machines sparingly – mainly for timber prep – as like Gary above I prefer to do the fun stuff by hand. One thing that might help might be if TV ‘experts’ didn’t remove guards ‘for clarity’ – I think we can all work out what’s happening under the guard without that. The trouble is that the subliminal impression it gives is that being able to remove the guards is a sign of expertise . . .

Could I suggest that you lower that crown guard and bring the riving knife closer so it’s doing its job. I’ve worked with to many guys who don’t know how to set up guards correctly or even understand how they work for you to stop you loosing a finger or breaking your arm.

Thanks, though I should note that the saw shown here wasn’t in my workshop and had also been out of service for several decades.

Cheers.