Are hand cranked grinders the toy that we all want to work?

Are hand cranked grinders the toy that we all want to work?

Now honestly, I’ve never had any success with them.

I can’t make much sense of them as a sharpening tool at all, so perhaps I’ve never given them a fair trial.

I avoid grinders altogether until it comes to that horrible A2 stuff. And at that point I need a grinder with pin point accuracy, no vibration and a true and sturdy support. Along with being able to shift a tonne of material quickly.

Anything other, and I’m wasting my life as well as steel.

This Tormek grinder is what I use for establishing bevels and sharpening any thick plane irons or harder A2 steel. On the whole though I use softer irons and can get away without a grinder in my sharpening kit at all. If you’re looking to learn to sharpen or improve the efficiency of your sharpening routine then have a look at our ‘Get Sharp’ video course where we go through everything you need to know to understand and maintain sharpness & improve your overall experience with hand tools.

But these hand cranked things seem really popular.

I could understand as a rough repair tool in an otherwise grinderless and ‘A2 free’ environment. But how do you find them for an actual sharpening routine?

I’m keen to know, because I’ve always wanted to make one.

I like the idea.

But I’m not thinking small bench top grinder. I’ve always wanted to make myself a big water wheel.

One of those huge sod off ones, the type you’d sharpen a sword on.

Probably just a thought, I have no swords (well I do, I have one).

But how have you gone about creating or buying a cost effective, human powered grinder?

Perhaps foot power would be a good solution?

Maybe something on the end of a foot powered lathe?

![How do I Sharpen a Router Plane? [Q & A Video]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/11/how-to-sharpen-a-router-plane-video.jpg)

It might be interesting to make a hand powered belt sander/grinder like the knife sharpening guys use.

Then, you just need a flat surface, two wheels and a belt…. power off your lathe or throw together a treadle of some sort.

Richard, get yourself a CBN wheel, either on an 8″ half-speed grinder or for your Tormek. It’s a game changer.

Regards from Perth

Derek

To add a comment about hand grinders and CBN wheels:

I have had a few hand grinders over a couple of decades. The sentiment is a nice one – and very romantic. The reality is that all the one’s I have had wobble. This, along with the single-hand support and movement of the blade, makes for an inaccurate grind. This makes for inefficient sharpening.

Now before anyone accuses me of OCD, sharpening is just a necessary evil as far as I am concerned, however I want the best edges but I want them fast. I am not that precious about the equipment – I would rather build furniture than sharpen blades. The secret to fast sharpening is to hone the least amount of steel needed, and a hollow grind is where it all begins.

A hollow grind gets you close … a clean and straight hollow grind gets you there. CBN wheels do not require any maintenance and they do not wear. As a result, settings may be left and not require adjustment, and the wheels run almost as cool as a Tormek (but without mess and wear). I use a 180 grit for all, and the resulting hollow is so clean I can often skip the 1000 grit waterstone and head straight to a 6000 grit.

Write up on the system: http://www.inthewoodshop.com/WoodworkTechniques/UltimateGrindingSharpeningSetUp.html

Regards from Perth

Derek

Derek,

I agree that the hollow grind is necessary for thicker irons, such as those found in bevel up planes. Bevel down, especially thin irons, are easiest to sharpen completely free hand, as both Richard and Paul Sellers do.

But I don’t agree on the necessity to make that hollow grind OCD-style perfect. I have an antique hand grinder, and its wobble is horrendous. So horrible that it knocks the sides of my Veritas tool stand all the while sounding like a bomb siren! But it doesn’t matter; the hollow grind is only there to remove iron quickly and establish the bevel angle. All sharpening and honing are done afterwards on stones, where accuracy is important.

There’s a place for even the crappiest hand crank grinders in all shops. Mine lives under the bench where I pull it out when needed.

But I think the real secret to these old guys is to use the coarsest stone you can get, something like 36 or 46 grit, Then it works super quickly and leaves such a rough finish, you have to rely on stones for the final sharpening and honing.

Jonathan Wright

DrawnWright

I have had tje good fortune of getting my hands on a 1914 pike hand cranked grinder, for 5 inch stones.

Since this thin was made when the Ford T was all the rage you cant expect it to have such things as ball bearings, it wobles a bit, but the small radius of the coarse stone is great for making the hollow grind an then the stones do the precistion work. Also, you can put a cheap honing guide on the tool rest (maybe cut a groove on the tool rest so it does not move forkard or backwards, mine has a groove already) and I have a cheap hand cranked grinder where I can fix the angle of the blade

Also, you can get used really quickly to using one hand on the tool and one on the crank, they had a handle because it worked fine, no need to reinvent the wheel there.

Greetings from Santiago de Chile

Mine just makes a funny noise…

https://youtu.be/7uqO8BJ9wSw

Enjoy.

I have plenty of grinding solutions (including a Tormek) I’d still like to see an unplugged grinder made. It’s something I’ve thought of but with limited shop time have never gotten around to.

Sounds like fun even if you don’t end up using it regularly.

I’ve found that there was no net savings in Canada compared to the energy expended over diamond stones so I got rid of my hand crank grinder. Plus you’re doing all that effort with one hand. The only idea I can think of that might be better is a foot treadle design. I’ll eventually get an electric grinder again.

I have used a hand cranked grinder since 1976. Even on the PM-V1 steel from Veritas. Took some learning like anything else but gets the job done. Mine is a 6″” with a hand made holder ala Krenov. I finish with diamond stones and polish with 1 micron sandpaper on glass.

…don’t know how “effort” became Canada…oh well.

My Grizzly Tormek-clone is all I need. I’ve thought about a contraption to drive with a treadle lathe, but that’s mostly to give another reason to build a lathe. All things considered, at my age it’s all probably a waste of time, money, and materials.

Isn’t Krenov the one that popularized the hand-grinder? I tried one from a flea market and detested it. I want both hands to control the tool and would rather not have the rest of me bobbing about while I try to control the tool. Also, the wheel diameter was quite small.

hi mate,

try a foot powered one, it leaves your hands free

i guess at first misread your headline

i thought you were going to show us how to make an organ grinder in our shop

haha

The last one I saw was one that sharpened knives. I really don’t want one.

I would like my dry bench grinder rotating a bit slower sometimes. A kind of variable speed setup would be nice. But I can’t think of a reason to drive it with muscle power, as long as there is electricity. This time I say “no thank you”.

I’ve seen tons of those hand crank grinders on ebay. I’ve thought about picking one up because I enjoy experimenting with old tools. At the end of the day, though, I simply couldn’t imagine one of those things being at all useful. It’s all the stuff others have already said in posts- small wheels, trying to work one-handed while spinning the crank, etc. Plus, I use mostly hand tools because they are pleasant to use as a hobbyist and actually quite efficient for a hobbyist. I like having the option of being able to work with minimal plans and just piece things together. I like being able to do this without layers of Kevlar, gas masks, riot helmets, and all that kit you are supposed to wear with machines. When I thought about it grinders just seemed like one of those things where modern is better. I couldn’t imagine one of those hand crank grinders being enjoyable to use. Now all that said, the idea of putting together a big water wheel is a bit of a different animal. Something big wouldn’t have to spin fast and could have a flywheel or otherwise be made in such a way that once it’s moving you wouldn’t need to constantly crank or peddle on something.

Love my Keystone Railroad hand crank grinder with 6″ Norton wheel

Works like a charm and you don’t produce enough heat to burn your steel

You use it to establish your bevel, then finish on the stones

I’m with this. I have a General (I think… .the red & black ones from Wisconsin), and as long as you get one that can take a 6″ wheel and have a way to make a bushing for the inevitable 3/8″ arbor it’ll inevitably have, I find it works well.

Norton makes their white wheel in 6″ but it has a 1″ arbor hole. Need that bushing.

I have found that it works really, really well. I fix irons with it (get nicks out) and use it to establish an initial bevel and camber. Everything else is stones. I don’t have electricity in my rented apartment shop for anything except lighting and the shaky benchtop drill press I use for a wire and buffing wheel so an electric grinder just doesn’t interest me.

My dad has a Tormek and it’s cool enough. He has the entire set of gizmos they sell for it as well, I’ve sharpened my hatchets on it as well as chisels and plane irons. But when it comes down to it, my $25 at a tool meet gets me through everything I’ll need a grinder for…and helps to keep me off that nasty Crystolon stone I have for the rough stuff.

Mind you it does take a moment to get used to. If you’re right handed, you’re cranking with that hand and doing the delicate stuff with your left. It’s less difficult than rubbing your belly and patting your head at the same time and the control is not an issue. Mark your line on the iron, turn the crank, quench (yes you CAN burn the steel with one of these!). You would do well to make a little tool rest for it, better if it’s adjustable for angle and best if you can make a small sled in a groove to keep things dead straight.

It’s just another tool in the arsenal for when you don’t want to sit there all day rubbing the rough stone.

I had a small hand grinder given to me by someone recently. I tried to use it but found the one handed thing too awkward.

I like the medieval water wheel idea though. Mount it on a wheelbarrow frame and it could be wheeled outside in the good weather and put out of the way easily. It would also be a good bit of fun at craft fairs etc. Hell, wheel it around sharpening knives, shears and anything else. Am I off on another planet or is there a business here?

there would be a market for learning how to make a treadle operated wheel as long as the parts are not going to break the bank. A Tormek is just way too much . . .

I have one, and it works.

***HOWEVER***

1. Cranking with one hand and holding the tool to be sharpened with one hand doesn’t make for fine accuracy.

2. I use it very rarely, only for the very worst repair cases. I’ve never found the need to grind tools that are otherwise kept nicely sharpened with stones and strop.

3. I have a treadle lathe and could easily mount a stone on it … but in the time it takes to change out the stone for whatever is in the spindle now, I can sharpen almost anything on the flat stones.

4. Once one learns to sharpen well on flat stones, without fixtures or training wheels, sharpening becomes very fast and easy. No need for rotating wheels at all.

Yet, that shouldn’t stop you from getting a monster wheel, building a water race from the nearest stream, and going into serious sword sharpening business.

Growing up, the hand crank grinder was the only grinder in my dad’s shop. He had every conceivable power tool in the shop except for the grinder. I didn’t know any better so I got use to it. I have it now in my shop but I also have an electric grinder. In fact it is one of the few power tools that I use. Doing the one handed thing is the main problem with one of these and that can be overcome if you have someone to turn the crank while you sharpen. I mostly use my crank grinder when I have a visitor to my shop or when doing a demo to help keep the nostalgia atmosphere intact. My shop is somewhat of a museum and it is important to keep the museum type of atmosphere. I always thought that a steam engine out back propelling a line shaft would be great when putting on demonstrations.

I restore a lot of vintage tools and sharpen all kinds of things, including HSS turning tools. I love the humble bench grinder: it can handle absolutely anything.

I couldn’t imagine using a grinder with only one hand, but I suppose a treadle version would be fine.

A little off topic perhaps, but for what it’s worth, I absolutely agree with Derek:: CBN wheels are amazing. I don’t think the word’s really gotten out about them yet, but if I worked for Tormek or Worksharp, I’d be updating my resume…

Having been in Tool & Die for the past 35 years a small bit of advice on wheels. Diamond works great on carbide and is used extensively for carbide. When we would grind hardened tool steel with a Rc of 50 to 62 CBN wheels would be used. If the steel is not hard in this range the CBN wheels would not work as well. Diamond has a tendency to wear out when grinding steel

I got one for $5.00 from a going out of buisness thrift shop. Around the time someone in the public eye touted them. Threw it away. Mass hysteria. Later I disassembled the waterwheel that powered the overhead shaft connected to my lathe by a handmade leather belt.

Growing up in the 1970s I had my grandfather next door (born 1900). He had a 3 foot (ish) sand stone foot powered grinding wheel. I love to sharpen the garden tools with it as a child. Though the wood has rotted, my dad (and I guess I) still have the wheel and the metal bits. We will be remaking the base for it during this winter.

If you are going to go through the hassle, I suggest you go big or don’t bother. It would look nice on your videos and blogs and provide another separation from you and the others.

By the way, I completely agree about A2 steel. I bought some premium planes and chisels that have it. I can’t stand it as it took forever to get a burr using Paul Sellers diamond stone method. I didn’t want to buy a new sharpening system. I ended up buying an extra extra coarse diamond stone and use that to start with my A2 blades. It gets to a burr quickly. I think progress to the other three diamond grits. They look just fine when I am done and it goes quickly.

Am I wasting steel this way? Probably but so what. As a hobbyist (in shop about 100 days a year for about 3 hrs per day), it’s unlikely I will wear them out. If I did, I would just buy O1 replacements.

Who knows, in the near future, I may just switch over to the big sand stone wheel for the first step. If it was good enough for our forefathers ……

Those hand driven grinders are not that bad. My father used his for for sharpening his tools, and we kids just loved to turn the handle. Doing that, we also learned about sharpening.

Very close to our house,lived a carpenter. He always used a big foot driven grinder.

His lathe was foot driven to. But h is band saw was driven by hand. A big wheel with two handles. When he hvad too cut out wood, he had help from two men from the town.

We kids just loved to visit him in his workshop. No elecktric machinery, anything he made was made by hand. Doors, tables, chairs, Wheels you name it.

If you want power and precision, variable speed, with both hands on the tool, check out the world of repurposed bicycles. The frame, pedals, and gearing system from a defunct bike will give you the base for any number of foot-power tools.

I love the idea of a low-to-medium RPM unplugged grinder, but not if it is hand-cranked. For my needs, Tormek is too much coin. The cheap Tormek clone I have is underwhelming for blade-holding accessories and precision.

Maybe I should look again at the two antique sandstone wheels hiding in my garage…

I bought a cheap hand grinder on ebay. Works good enough for me. No fancy steel. Just run of the mill plane irons and chisels. But I’m also just a hobbyist. So I don’t sharpen three times a day.

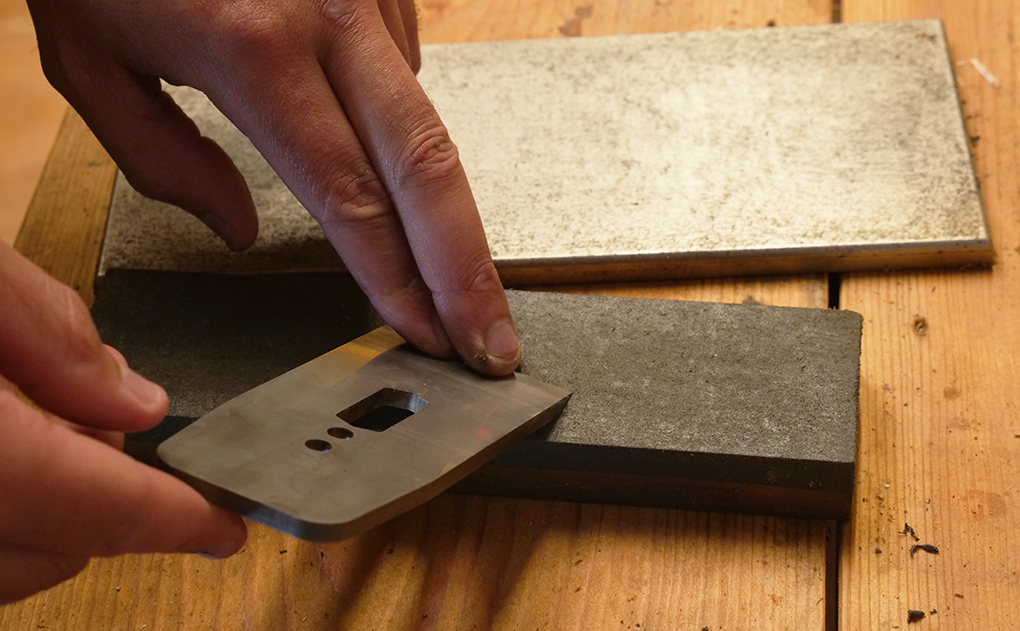

I built a jig to help “holding” the tool based on an article in the Woodworker. For plane blades it works really well. For narrower blades like chisels it can be a bit more fiddly and needs some training but so far I’m happy with the results. The grinder is just for the primary bevel. Finishing happens on some misarka oil stones and strop.

Here the jig: https://kotka.de/a42396518cc0bb880cdc6840be150653/IMG_0370.JPG

And the result: https://kotka.de/a42396518cc0bb880cdc6840be150653/IMG_0371.JPG

Timely blog topic. I just saw a 6” bench crank grinder at a antique store for $40, and on Craigslist nearby there is a foot pedal type larger one that would be good for axes and such. Kind of thought picking one up but would need a monkey to crank the hand one loke the old movies.

I have a collection of hand and foot grinders my favourite is the ‘Hayden Allball’ – 1,000 revs per minute! The 9″ wheel revolves horizontally on top of tube pillar that the foot pedal is attached to. The allball refers to the ball race mechanism in the tube. It was made in Redruth, Cornwall.. a real gem. For sharpening delicate carving chisels I use a large Edwardian yorkstone foot treadle. The 2.1/2′ stone revolves in a trough of water. To get an accurate angle I use a honing guide (like those used with bench stones) running on top. It’s great as you can never draw the temper. Fine Yorkstone is hard to equal.

Where do you get large fine grit stones?

Other than antique stores, I mean?

This guy made a business of it

https://patch.com/illinois/westernsprings/tony-delciello-knife-sharpener-guy-back-in-town

Here’s mine

https://www.flickr.com/photos/coalandice/4630327109

Hi Gang. As an actual user of a hand crank grinder, I have to say using one is like patting your head and rubbing your tummy at the same time..

The dream of having a grinder coast while grinding is not practical. Enough mass to overcome the energy loss for more than a moment will be difficult to get moving with a single hand crank.

I also use a treadle grinder. After truing up, the old wheel is 18″ diameter and 2″ wide. With the two treadles I can power through sharpening a 2 1/2″ plane blade, or a setting the bevels on a trashed 12″ draw knife.

Is it easy? Not really. Balancing on your butt while pumping your legs up and down is bad enough. Try doing that while freehanding a razor sharp draw knife. Now that takes practice. The fixturing helps. I’m stubborn. It works.

There is a reason for power grinders. When your helper grows up and moves out on his own, the electric grinder still keeps working.

I think what would make more sense is a slow turning abrasive wheel of some sort, driven by a motor out of a washing machine or similar. The wheel could be made from plywood, or could be a front wheel off a bicycle, with a strip of abrasive cloth cemented to the tire. (The latter arrangement was shown quite a few year s ago in the Methods of Work section of Fine Woodworking Magazine.) It would not take a genius to cook up a plywood frame with brass or bronze bushings in it, axles made from cold rolled steel, and with either a commercially-made abrasive wheel or some sort of home-made abrasive wheel. If driven by a belt on home-made pulleys, plus a low cost motor, speed could be whatever you wanted – no need to crank the wheel by hand, which as has been said by others on here, handicaps the user by occupying one hand to supply the motive power rather than leaving both hands free to hold the tool in the best way possible..

I work with a guy from Mexico. He told me that when he was a boy a man would come around on a bike with a grinder on the rear. The bike had a second seat mounted backward that he sat on to operate the grinder. Such as this one. https://youtu.be/gvCp-kc3tks

I think an important consideration that is missing in this discussion is the lack of slwo electric grinders on the market. I don’t understand why there is no variable speed electric grinder on the market: high speed for removing and shaping metal; slow speed for sharpening and establishing a bevel without the risk of overheating.

I have one and I consider it more of a novelty than a must have tool. I rarely use it anymore but did when I used to rehab a lot of old plane blades and chisels that looked like someone tried to open paint cans with them. They’re probably faster than your coarsest stone and slow enough not to blue the steel. If you take care of your edges you will probably never need one. One thing not really mentioned is that they are entertaining for kids and grandchildren alike. If you do find one cheap buy it if you like fiddling with stuff. Nearly all of the them will have old gunked up grease that needs to cleaned out of the gears so that it will turn easily

I inherited a hand cranked grinder from a grandfather. Installed a new 6 in wheel. Don’t use it a lot. Mostly for shaping screwdriver tips. Never burn any metal with it.

Nora Hall was an old world carver. She accepted a felt wheel with paste for sharpening her carving tools. Her daughters still sells them. They work quickly and don’t burn. Have mine mounted to an ancient electric motor. It needs to be a slow motor, like 1700 rpm or so, not 3000 rpm.

Hi: I teach woodworking at a summer 2 week campout I go to. no power available, so I needed (occasionally) a grinder. I had a spring pole lathe. I put a wooden arbor on a grinding wheel/stone. It works like a charm… be well

Karl

I found the small ones you clamp to your bench are not much good. I did get a standing one, bought a new stone and I must say truing the wheel with a dressing stone made a huge difference. It’s still only about 5″, but I use it to to grind axes and blunt or damaged plane irons or chisels and it helps if someone else turns the crank. I also have a big old manual grinder from my grandfather, maybe 16″, but the case is broken in one place. I still may try to get it in use, though.

On CBN, I would consider potential health risks associated with these, so I would use a respiratory mask if I used them.

I have a small antique hand crank grinder that I bought mostly to add to my collection that will go into an old tool chest. I have used it and I found it was very effective once I understood how to position the tool rest so I could hold the tool with one hand. Now if it’s something huge you want to sharpen a sword on I think you should plan on foot power. I’ve used the one my uncle had and worked ok for sharpening things like axes. I have a 14″ x 2″ pedestal grinder that runs from a flat belt. I don’t have it running yet but when I do it will have water on at least one wheel. Really for maintaining tools it takes very little. What I use most is a set of three diamond plates and chromium oxide on a strop. About the only time I use a grinder is when I’ve made a new tool or I just bought a used tool that some half wit boogered up.

strange this caught my eye, when I brought this house 40 years ago there was a hand grinder secured to the work bench, it had a trough for water and a left hand handle.tried it a couple of times ended up recovering from the bench and purchased a good two wheeled elerctic. grinder, but found latelt for finer work could

not slow it down enough.got the old one now 35 years in storage cleaned greased it set it into the holes still on the bench,gave it a turn it licked up the water and gave a perfect fine point and razors sharp.sometimes I just swing the handle up to,speed stop turning and away it So I can use two hands, while not a replacement from a.n electrical one well a joyous interesting fine working addition

David Aubrey

When I first began using tools we had a monsterous treddle Water wheel about 30″ x 5″ that sat over a trough of water. Great for sharpening our axes, but man that was sixty plus years ago. I’ve had a Tormek for some years and would not change it for anything, except maybe, A Sorby Belt system.

Pete

Sad to say that you put a question out there and you get more replies of negative problems than people with solutions ‘ creative craft community ?,. I have gone over to a hand crank grinder. Safer, quieter , variable speed , run it forwards or reverse. Get a quality grinder that runs true ,mine is a Mole of eBay. I put a CBN wheel on it you can get the bushes to make it fit from bearing supply companies . Very little dust is produced as wheel dosnt break down just the tool steel grindings . Many say that they find it difficult to crank with one hand and control the tool with the other. Easy solution , take the rest that comes with the grinder off ,mount the grinder on a board or bench ,

Mount the the rest system Tormek produce to use their jigs on a conventional bench grinder it works a treat you can use all their jigs to sharpen a multitude of different tools.

I’ve tried a few methods. A set of Oneway wheel balancers and rests transformed my grinding into an easy and pleasant experience- quick, easy, and gentle. Everyone worries so much about heat- just ease up a bit. There’s no need for slow speed, and many wheels work better and easier at high speeds. If you’ve got a conventional grinder already don’t start spending money for fancier systems.

Hey Richard you might like this video from a fellow Canadian

Tools: Sharpening wheel: https://www.youtube.com/watch?v=y3cMQ7d2S0k

or

This Unorthodox Video

How i sharp my chisels : https://www.youtube.com/watch?v=1aFWkUJs-0c

or another great Canadian

MDF Buffing Wheel: https://www.youtube.com/watch?v=oFiqlTmSOX0

Cheap And Easy Sharpening “Stones”: https://www.youtube.com/watch?v=-txq8Sv6l2k

and I would like your opinion on:

Sharpening to 250-grit: https://www.youtube.com/watch?v=UbAo4RpM7oM

Thanks and Enjoy

Talking about kick-ass grinders. Albeit not hand-powered. (Ca. Min 8:10)

https://youtube.com/watch?v=jZUrxSpcwWY

The Blaupließters in Solingen also use wooden wheels with a natural grinding compound from the greek island of Naxos. (Ca. Min 9:30)

Maybe missing the topic a bit, but interesting nonetheless. Also sorry, but audio is in german.

Too much lying down on the job?

https://www.dozorme-claude.fr/wp-content/uploads/2014/11/photo_coutelier_RVB_1900.jpg

https://i.pinimg.com/originals/4c/d1/87/4cd1877fa7872dc26ac88534f409f3fa.jpg

http://www.leevalley.com/us/shopping/techinfo.aspx?p=47854

Roy Underhill is the PBS equivalence of you in America. I’ve actually tried a foot powered sharpening wheel and if I was truly into full time woodworking, it has appeal. I use buffers and cutting compounds for roughing my tool and finish on diamond hones most of the time.

A revelation awaits the woodworkers here . Watch the video of a “Woodworker turns Chess Pieces on a manual powered lathe with hand and foot” .He uses a Moroccan Bow Lathe, Right hand works the bow ,Right foot holds the blade onto the bar while left hand turns the blade handle.. and controls the turning chisel . .The left foot is just used to stabilise himself .

Try that .

Apartment dwellers everywhere, like me, want a hand cranked grinder because then the mess and noise of grinding can be easily and quickly taken outside where it won’t bother our neighbors and landlord, and won’t scatter grit and (to a lesser extent) swarf in our cramped interior quarters.

A cordless grinder could work too, I suppose, although any cordless tools get you into a fair amount of money for the battery and the charger if you aren’t already settled into a cordless brand.

I’m an apartment dweller myself, but I’m very happy with my electric grinder. It’s extremely quiet — certainly nothing that would bother neighbours or housemates (a handsaw going through 2″ maple is *much* louder!).

Dry grinders do shed grit and swarf, but that’s easily vacuumed up. If you want to reduce the mess to almost nothing, swap out the stone wheel with a CBN one.

I’m not OCD, but I appreciate an easy, perfect edge. I have used a hand grinder for sharpening for over 40 years. It is possible, even easy, to get the stone perfectly trued, and an accessory tool rest is essential. Once those standards are met it does a better job than a power wheel: smoother, less burn, better control, less noise and danger.

But like every other fine tool, if you expect to sit down and use it perfectly and with skill the first time you try, you will be disappointed.