Fast, Efficient Sharpening. At the Best Price!

You’ll find that the cost of your sharpening stones scales with the cost of your tools.

More expensive stones won’t mean they’re better for the job if they’re incompatible with the type of steel that you’re using.

If you’re working with the types of tools that I recommend, things like the older Stanley hand planes and low cost chisels made from O1 steel, then you’ll find that the best sharpening kit for you is also the cheapest.

These run of the mill tools have such soft steels that the best sharpening stone is without a doubt a double sided Norton oil stone.

A Good Sharp Edge. Simply.

If you want to get a sharp working edge on softer steels then you can keep your sharpening kit incredibly simple. Just use the double sided Norton, and the job’s a good’un.

No need to fret about higher grits. It’ll work and give you a really manageable and efficient sharpening routine that you can keep on top of easily.

A Longer Life For Your Sharp Edges.

If you want to take it a step further and increase your edge life then you can make yourself a strop.

Strops are very simple to make and are an incredibly cheap way to introduce a finer stage to your sharpening kit.

Stick a bit of suede to a bit of wood and rub on some polishing compound. This Veritas one is very fine, but I find it works a treat.

It’s very easy and cost effective to make your own strop & it’s the perfect bit of kit for polishing your edges, particularly for cambered plane irons.

A Faster Sharpening Routine.

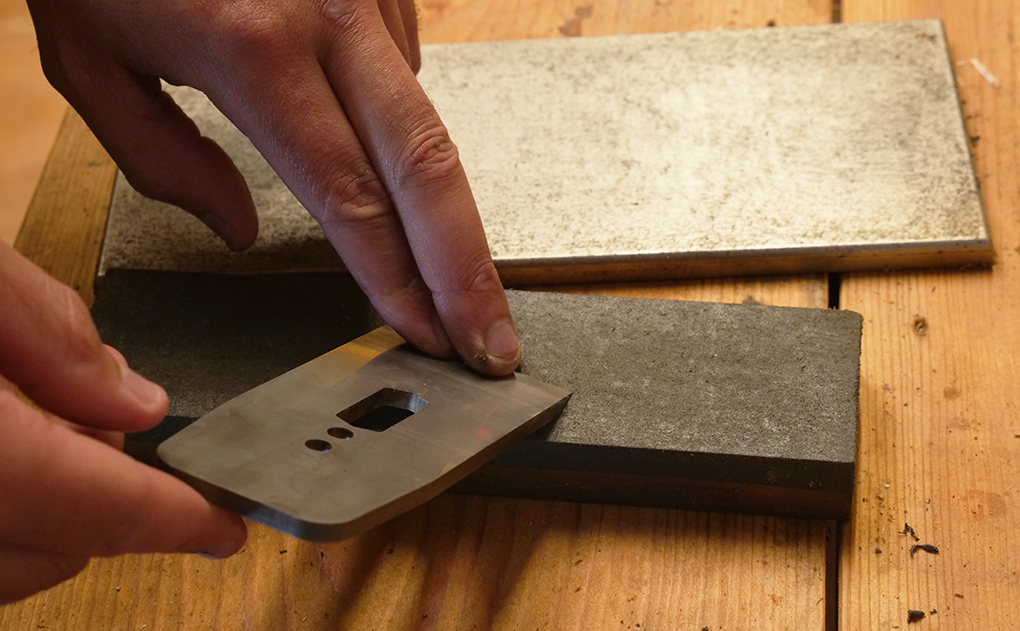

If you want to gain speed in the rougher sharpening area then you can replace the coarse side of that Norton oil stone with a coarse diamond stone.

I recommend going for the coarsest diamond stone that you can get.

The optimum sharpening kit for your softer steels: Coarse diamond plate, fine oil stone, polishing strop. These are all I use for the majority of my sharpening needs & the sharpening routine is so fast that it encourages you to always keep your edges ready for action, as well as allowing swift changes to your bevel angles and cambers to optimise for a specific task.

Choosing Your Sharpening Stones | Thoughts on Grits.

The Oil Stone

Sharpening can feel like a science and it seems that when people struggle they start looking for numbers hoping that finding some secret figure will make things click.

The real secret is in letting go of all of that scientific maths.

I don’t get into that whole grit thing when buying an oil stone.

As long as one side’s fine and the other is coarse it’ll kind of do the job.

Oil stones are very good at clagging up and burnishing so before you know it the fine becomes super fine. I say this as a good thing.

Oil stones are very good at clagging up and burnishing so before you know it the fine becomes super fine. I say this as a good thing.

If you’re setting up your sharpening kit from scratch and going for the fully fledged option (complete with diamond stone) then you can skip the coarse oil stone entirely and opt for a single sided fine oil stone instead.

The Diamond Stone.

Adding the diamond stone to this kit is all about adding speed, so the coarser the better.

If you’ve got the money, the best diamond stone you can buy is probably the extra coarse DMT lapping plate.

It’s a beast, a massive thing that can burn a primary bevel on in seconds.

I use this type of diamond stone for multiple jobs including flattening other sharpening stones, general restoration and tool maintenance so it sees plenty of use in my workshop.

If the DMT is stretching the budget then you can go with a much smaller diamond stone for this job. Since we’re using it for roughing the primary bevels only, precision is not vital.

Maintenance For Your Sharpening Stones.

While cheap tools allow cheap sharpening stones, a simple kit also allows for a simple sharpening routine.

A quick touch up to flatten the face once in a while is all that’s needed to maintain your oil stone. And to be honest you can get away without this at all.

Rub it a bit on your coarse diamond plate and job’s a good’un. It’ll freshen up the cutting edge and maintain flatness of the stone but as I say, it really isn’t essential.

My methods of sharpening are very, very forgiving in this regard so I haven’t flattened mine since we filmed the Get Sharp series. And it’s had a lot of use.

A Super Sharp Edge

If you’re worried that cheap and simple are sounding like compromises then don’t be. This is the setup for getting super sharp edges that can make your hand tools a true pleasure to use.

Just remember, don’t even look at an oil stone is what you’re trying to sharpen is made of A2 steel. The sharpening kit described here is for your softer steels only.

For a complete guide to sharpening your edge tools, including the set up for harder steels, methods, routines, angles, cambers and all the other scientific maths have a browse of our ‘Get Sharp’ video series.

![How do I Sharpen a Router Plane? [Q & A Video]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/11/how-to-sharpen-a-router-plane-video.jpg)

After watching the get sharp series I brought myself the kit reccomend here together with a cheap as chips second hand Stanley no 5. I was convinced that this old plane that cost me next to nothing would not perform as in Richards videos. I was so wrong. I could not believe the full length shavings that were flying off this peice of wood I had clamped to my picnic bench (great temporary outdoor workbench)I was like a man possessed desperately trying to bury myself in wood shavings. I’m happy to have both saved here on tool cost and got an older tool to work well. The noise of this plane is Seriously bloody satisfying.

I’ve got a mix of OEM Stanley and Record blades, O-1 blades, and a couple of A-2 blades. I’ve got some moderately older Sorby bench and paring chisels and several O-1 chisels. Your system obviously wouldn’t cover all my edges, but I have good results in short order at very modest price with a medium and an ultrafine Spyderco stones.

For rough work on chipped edges, I have a coarse diamond stone, or if there’s a lot to grind away, I use 80 grit paper on a granite plate; the 80 grit is faster than the diamond. My DMT diamond stone is not as coarse as your flattening stone, so that might do as well or better than the 80 grit paper.

The ultrafine Spyderco does so well that honing on a strop does not produce any detectable gain.

Great post, Richard. I think the new people will have an easy time at the sharpening station after reading this post and watching your sharpening video. I myself use diamond plates (300, 600 & 1200) then always finish with a homemade strop. I’ve been doing it this way for years and for me, it’s the easiest. I like my chisels to be as sharp as scalpels and it only takes but a few minutes to true up a chisel. I take a bit longer on irons as my plates are not the large width. The irons I only make razor sharp and you could shave with them if you were so inclined. New chisels and irons take me about 15 to 20 minutes to get them to the way I want them. Most important, like you, I do not worry about the math, I sharpen the wedge angle and back to work. Note: I do not use micro bevels, never did and never will.

Cheers!

I bought 4 Lie Nielsen chisels and 4 Ashley-Isle chisels (same sizes for both). I use diamond stones to sharpen (coarse, fine, super fine). The Ashley-Isles sharpen well. The Lie-Nielsen chisels are a royal pain to sharpen to the point I’ve considered selling them (after all, how many chisels does one man need). Any advice on what I can do to make things easier for the Lie-Nielsen chisel sharpening? Many thanks.

Hi Joseph, your issue is you’re able to compare both steels side by side. Your best bet is diamond stone for hand sharpening A2, at least for the coarse stuff, and then start arsing about with the water stones. Or you could get a water stone grinder for the bulk and then fine polish on a water stone.

Truthfully though I do believe (without meaning any offence to any business) that A2 and a chisel is a stupid idea. They’re just so think mixed with the hardness, if it was me I wouldn’t splash out, I’d sell them.

Thanks Richard. I will likely sell them. Too much of a pain to sharpen. As such, I’m less inclined to sharpen which is the exact opposite of what I should be doing anyway.

I have and use a fine Arkansas oil stone by RH Preyda, (sold by Classic Hand Tools in the UK). I use it in conjunction with a coarse diamond stone in the same system Richard shows in his Get Sharp -series. I have read reviews where it has been mentioned that Arkansas stones work well with A2. You would only have to invest in one fine stone if you have no issues with coarsing the primary bevel on your diamond stone.

Nota bene, my tools are all high carbon steel so I have no personal experience with sharpening A2 on an Arkansas stone.

I reread your post, your video series talks about harder steels. I’m set, please disregard my prior email.

The “get sharp” series does a great job on sharpening systems for A2 steel as well, and answered all of my questions on sharpening, in conjunction with the free youTube videos. It has many time-saving suggestions, ways of simplifying, and explanations of mysterious things, that I felt tremendously confident since watching it and was able to figure out and solve problems on all of my planes. No more mysteries, no more obstacles. On to challenges in design and materials rather than tool maintance which now seems easy and completely understandable.

I notice Dia has two large diamond lapping plates these days: one is 120 grit, the other 160 grit. So I’m heading for the 120 grit unless soneone has a better grit to recomnend. I haven’t checked all the US vendors yet, but “sharpening supplies” had a lower price than others I’ve seen.

Thanks Jim, it’s great to hear that sharpening has become easy – the way it should be. With regards to the diamond plate, for its purpose I would go for the coarsest, so that 120 grit.

Cheers.

Hi,

I use VERY cheap diamond stones. you know, the ones with the diamond-shaped holes in them and coloured plastic backing plates. I have removed them from the plastic plates, glued them to some ply, put a strip of wood on the bottom of the ply to hook on the edge of the workbench.

With cheap spray oil, I work through the four plates and then strop. I can shave hairs off my arm and get wood glassy smooth.

The only job these will not do is small chisels. the wholes are too big and the blade will not run smoothly over the surface. I use my expensive diamond stone for these.

Doing this, most of my work is on the cheap stones, though they have lasted many years and still sharpen well.

Thanks Andrew, it just shows you don’t need to spend.

I have DMT stones and a homemade strop, wish my course stone was even more aggressive for when I have a nick from dropping an edge tool (doesn’t happen too often now I have a tool well in my bench). Eze-lap are a little more cost effective I believe but I didn’t know about them when I got my stones. Nothing like having a simple set up so you can get on with the task at hand!

How well do you feel this system works with Chrome Vanadium jobs like the affordable narex chisels?

Mike,

I recently picked up a few of the ugly looking 8105 Narex chisels and have had no problem using an extra course Atoma diamond plate and single sided fine norton oil stone. I am still getting used to Richard’s method but even so I have been impressed with method and the Narex chisels.

Another tip. Keep an eye out at car boots and the like. I picked up a very fine charnel forest stone for next to nothing. And even a new dragons tongue slate stone can be fantastic for when you want an even finer finish. I have used both on my straight razor

Any thoughts on water stones?

I have a Japanese combination water stone for my kitchen knives. It works fine but I find it a bit fragile.

In time should I swap to an oil stone if I’m going to do lots of woodwork?

I really recommend buying the Get Sharp series if it is at all possible for you. It has helped me considerably. I would not have thought I would watch hours of sharpening tutorials. Now, I have seen them several times. They are very engaging.

In the series, Richard covers an oil stone process with softer steel tools, and a waterstone / grinding process with harder steels with plenty of why and how demonstration. It is not really about the type of stone, but the appropriate tool setup and sharpening process for the type of steel you are using.

I, too, was coming from water stones and guides, but I didn’t have the knowledge to use them correctly. Using the diamond + oil stone method, my soft steel chisels have gone from being shiny but compressing fibers until they shear off, to actually cutting. The difference is considerable.

I am also confident that when I need to use my water stones for my harder steel plane blades (just a couple, happily), I will be able to do it properly.

Does anyone know if this stone from Amazon is the one shown in this article?

https://www.amazon.com/Norton-614636855653-8-Inch-Combination-Oilstone/dp/B07HLQJVRR/

Thanks!

That is the stone I purchased. It works very well.

Hi Richard!

I have a few tools with A2 steel, and recentlly I begin to shapen It with an Soft Arkansas and hard black. Did you have already test the Arkansas Stones on your modern Irons. I have the Get Sharp series and I know that you talk about oilstones on A2 Irons. For a while I’m getting good results with them. Please, ler me know If you had any experience with Arkansas. And sorry about my english… I’m talking tô you from Brazil. Thanks a Lot. I love the way you teach

Hi Richard,

I am planning on using your set up for O2 steel with the diamond extra extra course 120x stone for grinding, a Norton fine which I have and strop which I have. I have a DMT Dia flat 10″ 160x (the finer one) as well so if I find the DMT Did Flat still works I’ll try that as the “grinder” as you do. I had used this stone for a LOT of prep for Japanese

planes (regrinding bevels) and many other hard task. Glad I’m over my Japanese phase. The stone seemed to not work very well anymore when I started setting up your simple system as in your video I purchased which is fantastic by the way.

I called the dealer sharpeningsupplies in the US and they said try it on a glass jar which did prove the diamonds are still there but doesn’t really tell me if its too worn in my mind? I then cleaned with comet/Ajax and a bristle brush and a white rubber eraser and it looks much better.

Anyway, I’m mainly wondering if you are still using this system and how your DMT Dia Flat is holding up?

I mainly use wooden planes and like the idea of using a more traditional honing and polishing method (I know grinding on a diamond plate isn’t traditional) without the mess of waterstones which I may sell.

I was thinking of ordering an Extra Extra DMT Dia Flat (smaller but as you say, its doesn’t have to be as large as the Dia Flat) which is under $100 USD rather than another Dia Flat which is well over $200 now ($300 Canadian!)

I was also thinking of getting a black or translucent Arkansas stone later to use after the fine India.

Thank you for the great videos and help!

Stephen