I’ve been having a good old tidy up and done that thing where you stumble upon a great big sod off vice.

Now, if you’ve been lingering around from our old days you may remember this thing.

This thing isn’t light. It’s a huge chunk of metal, aged yet perfectly functional – the thread and nut are wonderfully smooth and will almost certainly last forever. To my mind this really is beautiful.

It was rather nicely given to me by my good friend Richard Arnold.

He mentioned he’d had it for years and felt it was a great shame that is wasn’t getting used. It was one of those classic “when I get the time…” cases.

He give it to me thinking I was one of those “doer” types. And yet here it is, found waiting as just a screw still, several years later.

I think this is a common problem; a thing can be deemed to be too good to use. I’ve been waiting for a very special job, something that could be worthy of such a vice.

As woodworkers I think we can all be sods at times for doing this with wood as well.

Many of the greatest makers pass with a hoard of their best timbers sat unused. They never found that special piece.

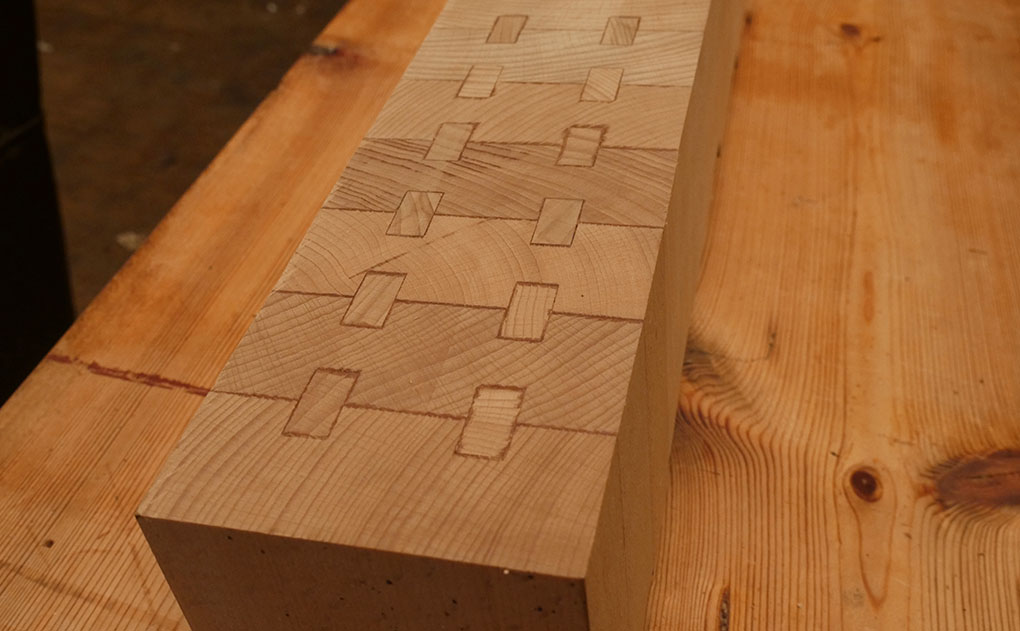

The thread is a full 2″ (50mm) diameter with a very coarse two teeth per inch. You can see it’s almost as substantial as a traditional wooden screw and will make a wonderfully fast face vice.

Well, I’ve decided. I’m building a workbench for this screw.

It may not become the greatest thing that matches this fantastic screw. But I’ve realised that doesn’t matter.

This screw is beautiful, but it’s also bomb proof and could easily be re-purposed on another bench in the future should I choose.

What’s important right now is that I follow through with my promise and actually put this screw to use.

I’m planning to cover a lot more about fitting vices in the future, but for now if you’d like a bit of guidance on choosing a face vice, then you could have a read here.

And while we’re on the topic of work holding, you may want to learn how to use holdfasts to improve the flow of your work.

![Simple Work Holding For Ploughing Grooves [Without a Tail Vice]](https://www.theenglishwoodworker.com/wp-content/uploads/2022/07/workholding-without-tail-vice-copy.jpg)

A friend of mine told be about a leg vise that he saw at a flea market. I did buy it for a whopping $18 and then began modifying my workbench to accommodated my new purchase. This vise had all of its parts and everything was in great shape. I did have to extract 60+ brads that probably somebody’s grandkids hammered into the chop. I also stripped off the red paint and found that the chop was made from birdseye maple, what else can go right. If I ever build another workbench this will be included in the build.

Richard –

This project would be a great addition to your online video series.

I agree Bro!

I know what you about not wanting to use something. A couple of years ago I was given an unused Marples wooden jack plane and an unused Footprint panel saw from the 1970s.

They sat in a cupboard for months. I couldn’t bring myself to use them. I sold them . What the new owners did I have no idea but I just couldn’t be the first to scratch them .

I once watched a show on the Discovery channel about a guy doing some insane stunt on a dirt bike. Of course he needed a brand new custom built bike for the stunt, and of course we had to see him try it out for the first time. He rode over a sand dune, let go of it mid air, and it slammed into the sand. He then picked it up and said “now I don’t have to feel sorry about getting scratches on it”.

No tool is too pretty to be used for its intended purpose

I had a similar problem. I picked up a screw and nut (no chop) at a flea market about 6 years ago and it sat on top of the shelf in the library, Last summer my neighbor gave me a stack of boards from an old bridge. That was the piece I needed to finally built a Moravian bench to put it to use. The boards and the screw have a new life in my shop.

No point in just looking at it, build the bloody bench!

I managed to get hold of an old Marples 2″ wooden screw and nut attached to a muckle hunk of timber for £30 on Ebay (to this day I’ve not a clue what it was originally used for) but it spurred me on to start your English workbench project. Couldn’t bear to just leave it on a shelf!

Only trouble is, now that it’s complete I’m stuck with the shiny veritas front vise which I was originally going to fit. Guess I’m going to have to build another bench just to put that vice on!

I find myself in exactly the same position, although my vice is in no way as glorious a find as the afore mentioned, but then I am one of those types if there is indeed a type for me to fit into, but I am never happy for long and always notice ways I could improve my bench, so the fitting of my face vice isn’t as much an upheaval as yours.

“This screw is beautiful, but it’s also bomb proof …”

I would expect a bomb proof bench for a bomb proof vise. Can’t wait to see what you come up with.

Oooooh, Richard, that IS a lovely vice!

It’s shameful, really, to think about some of the things I have in my shop that aren’t being put to use because I *still* haven’t decided precisely where to put it (like an old cast iron swing out seat I found on eBay before Benchcrafted started offering them for sale – it just needs a new seat and four lag screws into the leg of my bench and I’ll be sitting pretty).

The weird thing is that I’m not at all like that with things like tools. I have tools by some great contemporary makers in my shop and I use them all the time and without hesitation. It’s the greatest compliment I can give the makers, I think.

But that massive old 15lb holdfast (like the Record holdfast, with the screw function to tighten it down, you know?) with the thick acme threads and wonderful mass that just needs one or two 1″ holes in my bench to get put to work? Nah. It’s such a wonderful old tool I need to be sure and very precisely plan my holes in the top of my bench before I do anything with that!

I was going to have a big tidy up too and found I had a bloody great vice as well. It’s called procrastination.

Christopher:

I suffer from that too. Mind you, at 80 years, it does take time to get into the shop. All those years ago I should have built closer to the house I guess! Still I just replaced my broken 4 1/2 Record smoother, so maybe fettling that will spur me on!

John

I know there’s more to life than building benches, but not much more.

Richard building a bench, who’d have thought. This’ll be GOOD.

(and can we talk 2 1/2″ screws some time?)

Wow, I guess this vice screw just remained from an era where everything was meant to last forever.

For what kind of job wouldn’t it be oversized? But then, that doesn’t hurt anybody, does it.

A bit like Richard’s beautiful wooden vice screw, of which I am happy to have one ;-).

Talking about timber I have a big knarly piece of big oak. I’m afraid to use it because it’s anywhere between 2000 and 4000 years old. I was thinking of building a coffee table with a glass top and a kind of box frame to display the big oak within. Maybe cross cut rounds out of it. I feel such a responsibility to the material though.

Grrr *bog oak* not big oak. Bloody predictive text.

I can’t wait to see the bench you build this into, because I have a screw almost identical to yours. Just the metal parts, no handle or chop. It’s a total of 16″ long, from one end to the other.

The screw comes from my grandfather’s bench, and since I’m 62 it’s a really old screw.

One difference is with the flange that fastens to the outside of the chop, between the chop and the handle. (Pardon my terminology. I’m a recent entry into the woodworking arena.) On mine, the flange is domed on the side that fastens to the chop, which means you would have to do more than bore a hole big enough for the screw. And the hole in the flange is oval instead of round.

Do you know why the flange piece is designed that way?

Hi Richard, I acquired a one-inch diameter version of “that screw” that had initially belonged to a woodworker in the British Rail workshops at Kings Cross. The flange on the handle end looks very similar, although the screw-threaded “fixed” section on mine is a rectangular section iron. mouding. It’s part of a vice that I’ve fitted it up to me bench as a leg vice. Do you know anything about the manufacturer : I can see no makers marks. Now to stop faffing around researching tool histories and actually do some woordworking…

regards, and all the best, love your vids and your work

Carlos